Application of Magnetic Materials in the Aerospace Industry

The aerospace industry demands materials that can withstand extreme environments while ensuring precision, safety, and efficiency. Magnetic materials play an indispensable role in modern aircraft, spacecraft, and satellite systems. From navigation and propulsion to power generation and control systems, magnets contribute to the reliability and advancement of aerospace technology. At HS Magnet, we supply high-performance magnetic materials engineered to meet the stringent requirements of aerospace applications.

Navigation and Guidance Systems

Precision is paramount in aerospace, and magnetic materials are at the core of many navigation and sensing technologies.

Inertial Measurement Units (IMUs): While not exclusively magnetic, some IMUs use magnetic sensors to supplement gyroscopes and accelerometers, providing a more robust and accurate estimate of the aircraft’s orientation and motion.

Magnetometers: These are a type of magnetic sensor used to measure the strength and direction of a magnetic field. In aircraft, they act as a sophisticated compass, providing a stable heading reference that is not affected by gyro drift. They are essential for a wide range of navigation and attitude-sensing applications, from small drones to commercial airliners.

Motors and Actuators

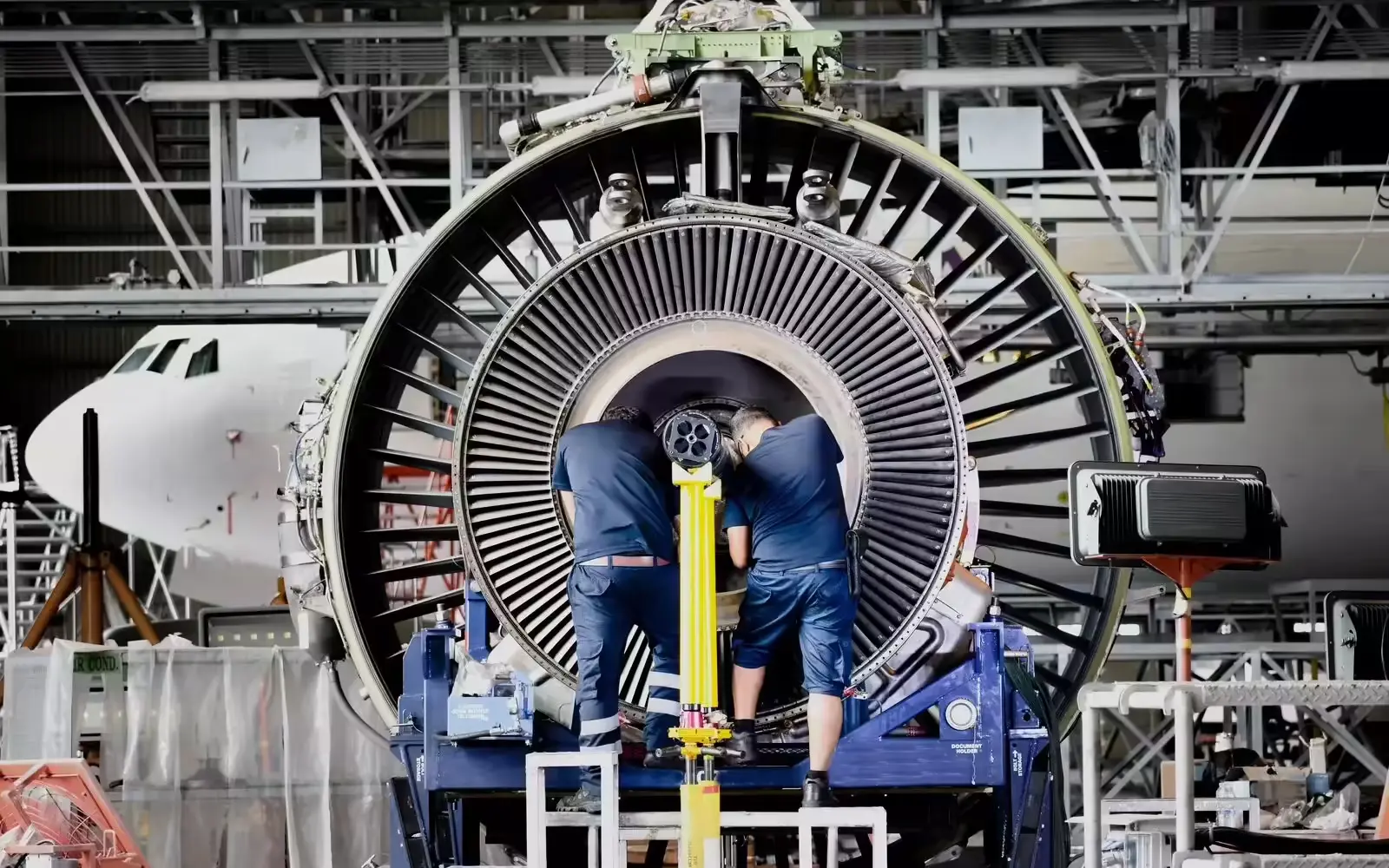

Modern aircraft are increasingly replacing heavy hydraulic systems with more efficient and reliable electromechanical actuators (EMAs). These devices use electric motors to control everything from flight surfaces like flaps and ailerons to landing gear and thrust reversers.

Soft Magnetic Cores: Soft magnetic materials like silicon steel and ferrites are used in the stators of these motors. Their ability to rapidly change magnetization with minimal energy loss makes them ideal for the high-frequency operation of aerospace motors and generators..

Permanent Magnet Motors: High-efficiency electric motors, often using powerful neodymium (NdFeB) magnets, are used in EMAs. These motors are smaller, lighter, and more powerful than their conventional counterparts, which is critical for reducing the overall weight of the aircraft and improving fuel efficiency.

Advanced Applications and Future Trends

The aerospace industry is constantly innovating, and new magnetic materials are enabling exciting possibilities.

Magnetorheological (MR) Fluids: These “smart” fluids, which contain tiny magnetic particles, can change their viscosity and stiffness when a magnetic field is applied. This property makes them useful for next-generation vibration damping systems in aircraft landing gear, providing a smoother ride and reducing structural stress.

Magnetic Bearings: Some advanced systems are exploring the use of magnetic bearings, which levitate a rotating shaft using a magnetic field. This eliminates friction, reducing wear and tear and allowing for higher rotational speeds. This technology is being explored for high-speed rotors in engines and turbopumps in rockets.

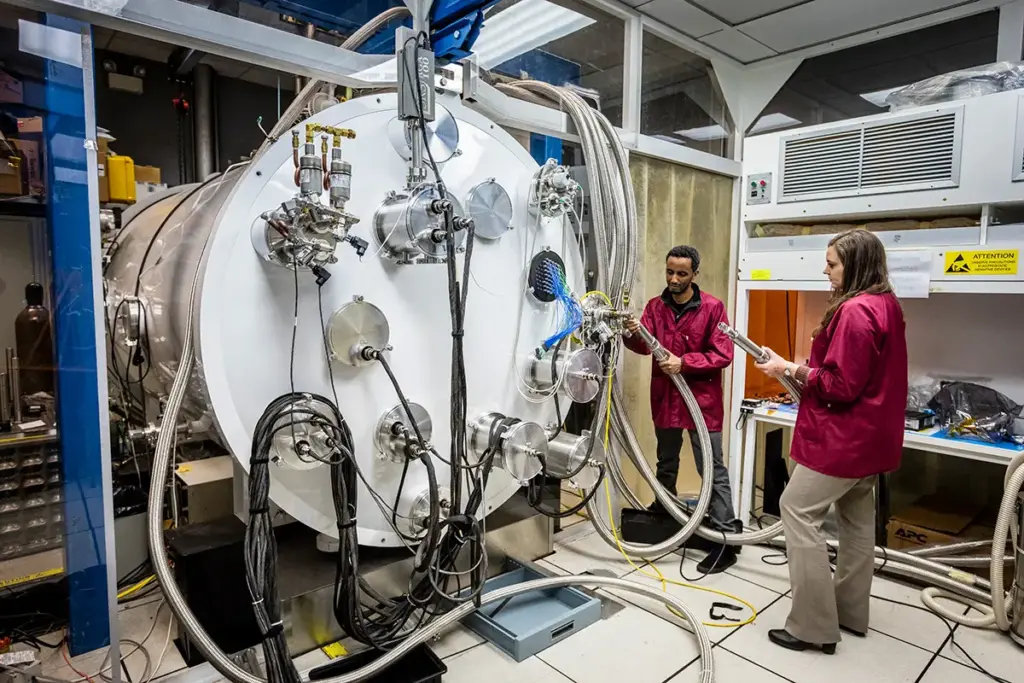

Magnetic Shielding: Sensitive electronic equipment, especially in spacecraft, must be protected from external magnetic interference and radiation. Soft magnetic materials, like permalloy, are used to create magnetic shields around these components, ensuring their reliable operation.