Permanent Magnet Manufacturer in China – HS MAGNET

With over 20 years of expertise, HS MAGNET is a leading permanent magnet manufacturer in China, specializing in Neodymium magnets (NdFeB), Samarium Cobalt magnets (SmCo), AlNiCo magnets, Ferrite magnets, and FeCrCo magnets. We provide high-quality magnets for motors, loudspeakers, generators, sensors, medical devices, and dozens of other applications across the globe.

From prototype development to mass production, our experienced engineering team helps customers choose the right magnetic material for their specific needs. Our knowledge of magnetic materials ensures the perfect balance of performance, cost, and reliability.

Why Choose US

Over 20 Years in Magnet Manufacturing

OEM & Custom Magnet Design Services

Export to 50+ Countries Worldwide

About HS Magnet

Founded in 2005 and located in Xiaoshan District, Hangzhou, just 4 km from Hangzhou Xiaoshan International Airport, HS MAGNET covers 20,000 square meters of manufacturing space with an annual turnover of over 100 million USD.

We integrate design, production, and sales under one roof, enabling us to respond quickly to customer needs. Our permanent magnets are widely used in industries such as:

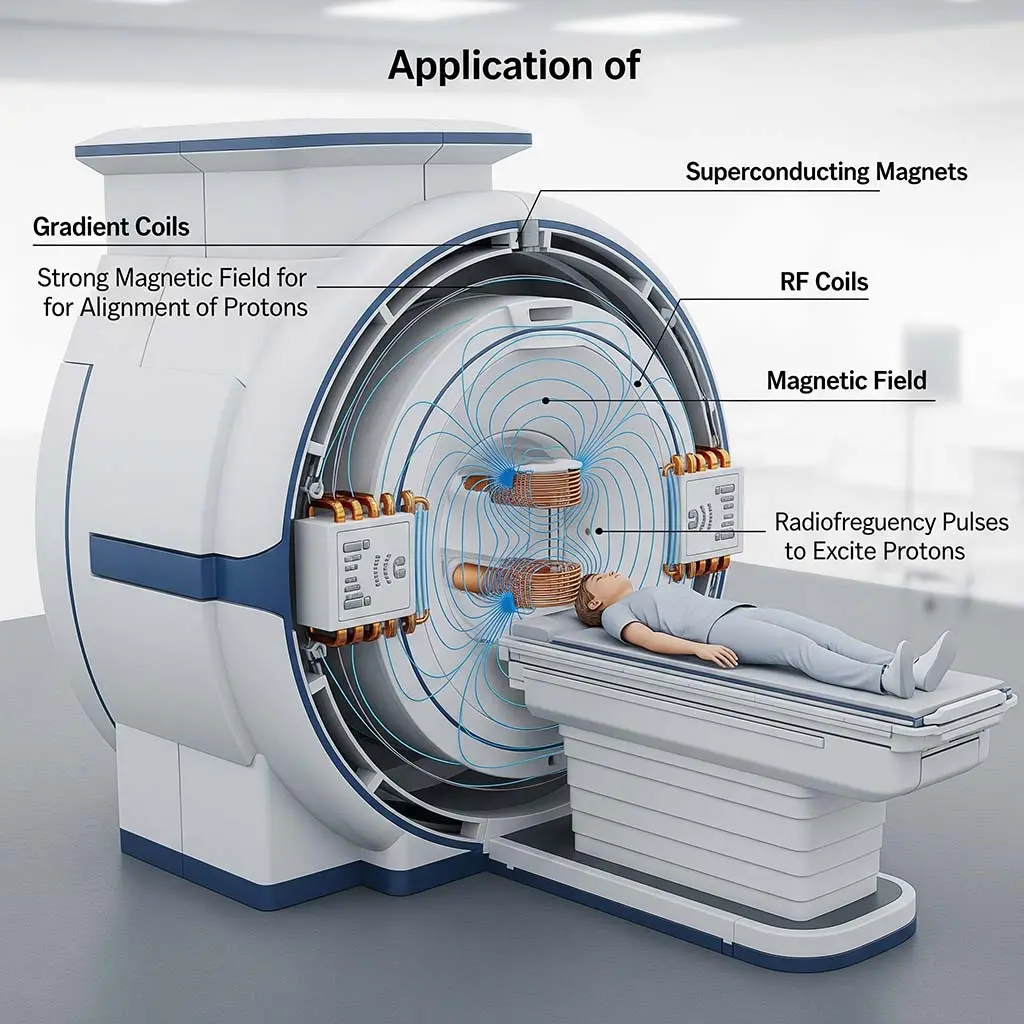

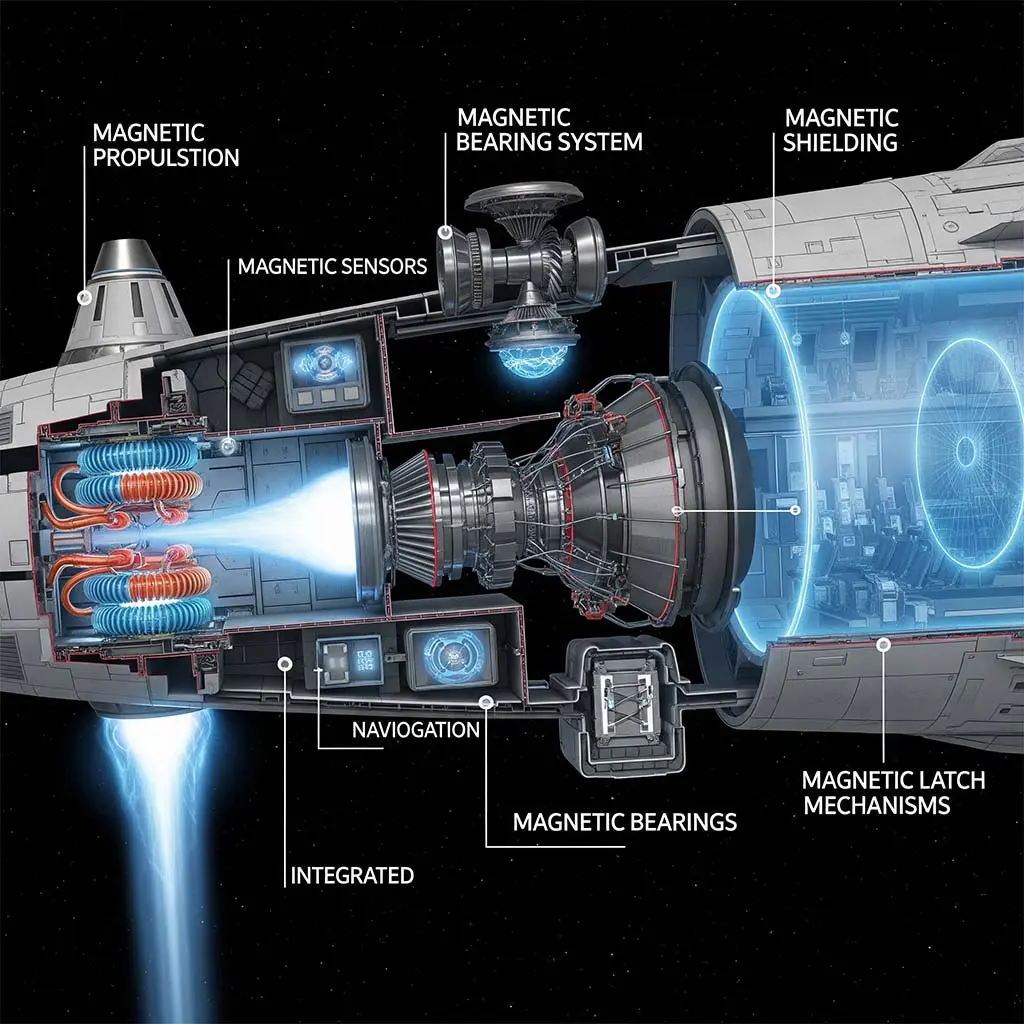

- Aerospace & medical technology

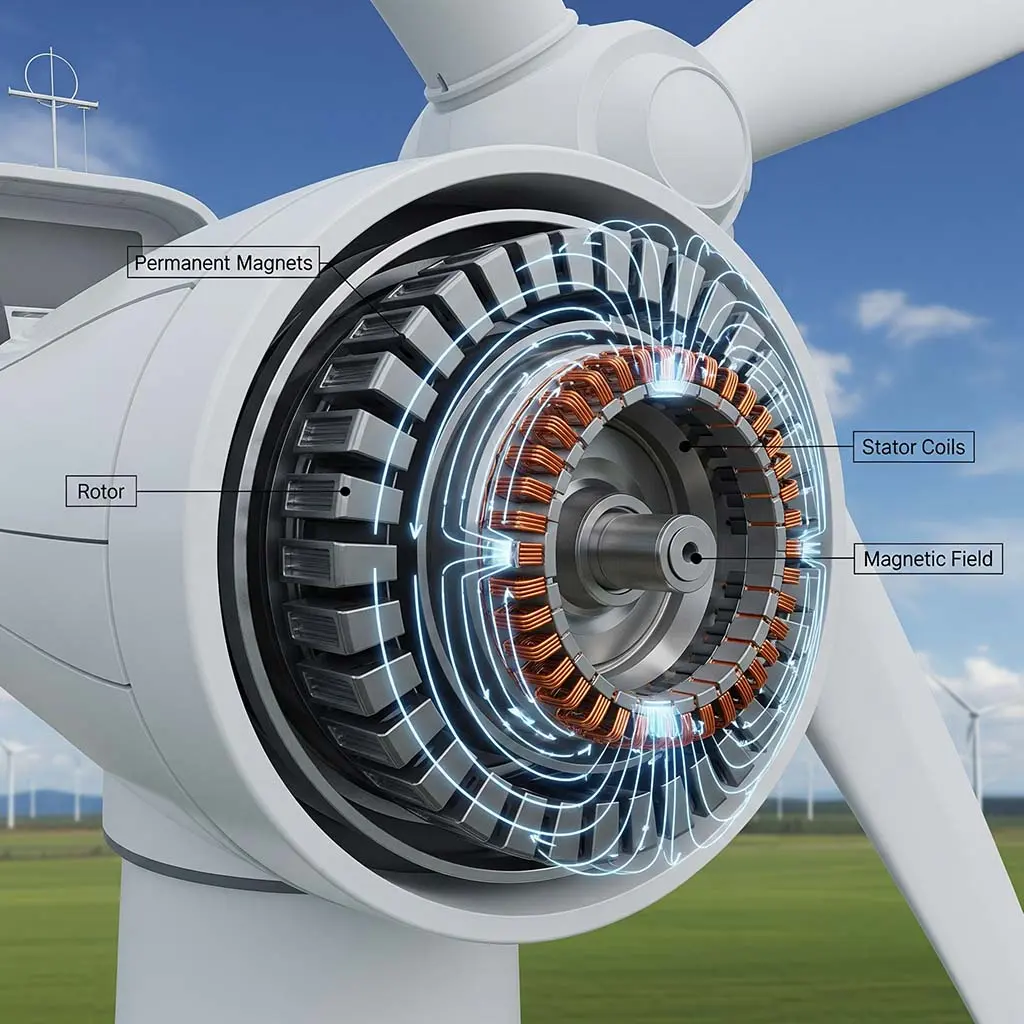

- Electric motors & generators

- Loudspeakers & audio systems

- Sensors & measuring devices

- Wind power & renewable energy

Manufacturing & Quality

At HS MAGNET, we operate under a strict quality management system. Every stage of production — from raw material selection to final inspection — follows rigorous testing standards. Our motto is simple:

“No unqualified product leaves the factory.”

This commitment has earned us the trust of customers worldwide, making HS MAGNET a reliable partner for long-term cooperation.

- ISO 9001 Certificate

- IATF 16949 Certificate

- ISO 14001 Certificate

Product Categories

Alnico Magnet

High temperature resistance, stable performance

NdFeB Magnet

Strongest magnetic force available, Rare Earth Magnet

SmCo Magnet

Excellent temperature stability, Strong Magnetic Force, Rare Earth

Ferrite Magnet

Cost-effective, corrosion-resistant

FeCrCo Magnet

Flexible shaping and machinable, Alnico alternative

Magnet Assembly

specific functionalities magnetic components