Hump magnets, also known as plate chute separators, are essential devices in industrial settings for removing ferrous contaminants like metal particles, rust, and iron filings from free-flowing materials such as grains, powders, plastics, and liquids. Invented in the mid-20th century to enhance product purity and protect machinery, these magnetic separators are widely used in sectors like food processing, pharmaceuticals, chemicals, and recycling. Typically housed in durable stainless-steel casings with hinged doors for easy cleaning, hump magnets can be custom-designed to integrate seamlessly into existing production lines. Their efficiency stems from powerful magnets that attract and hold ferrous debris, preventing equipment damage and ensuring compliance with safety standards like FDA guidelines in food industries. In this guide, we’ll explore what hump magnets are, how they work, the magnets used, and their key applications to help you select the right solution for your operations.

What Are Hump Magnets?

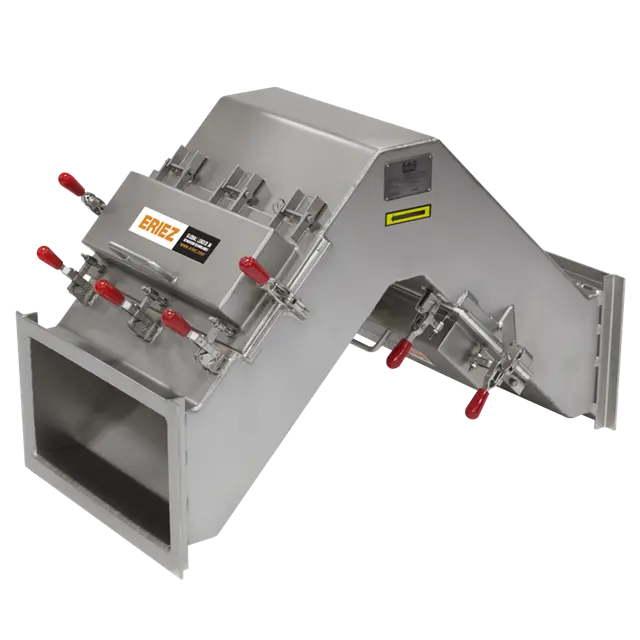

A hump magnet is a specialized magnetic separator designed to capture and remove ferrous particles from bulk materials in gravity-fed systems. It features a robust stainless-steel housing with one or two magnetic plates arranged in a “hump” or offset configuration to maximize exposure to the material flow. This design disrupts the flow, allowing magnets to pull out contaminants effectively.

Key benefits include ease of installation (often bolted directly into chutes or pipelines), low maintenance, and customization options for size, strength, and flow rate. Unlike simpler grate magnets, hump magnets handle high-volume flows and are ideal for vertical or angled setups. They are corrosion-resistant, making them suitable for harsh environments, and can be equipped with rare-earth or ceramic magnets depending on the required intensity.

How Do Hump Magnets Work?

Hump magnets operate on a simple yet effective gravity-fed principle, leveraging magnetic fields to separate ferrous contaminants. Here’s a step-by-step breakdown:

- Material Entry: Free-flowing material enters the top of the hump magnet housing via a chute or conveyor.

- Magnetic Attraction: As the material cascades over the hump-shaped magnetic plates, ferrous particles (like nails, screws, or metal shavings) are drawn to the powerful magnetic poles and held securely against the plate surfaces.

- Cleaned Output: The purified material continues downward, exiting from the bottom of the housing and proceeding to the next processing stage.

- Cleaning: Operators can open hinged doors to manually remove trapped contaminants, ensuring minimal downtime.

The effectiveness depends on factors like magnet strength (e.g., gauss rating), material flow speed (optimal at 10-20 m/min for most setups), volume, and contaminant size/composition. For instance, stronger magnets excel at capturing fine particles in high-speed lines, while proper sizing prevents blockages.

Types of Magnets Used in Hump Magnets

Hump magnets typically incorporate two main types of magnets: rare-earth neodymium-iron-boron (NdFeB) or ceramic ferrite. These are housed within the plates to generate a strong magnetic field.

- NdFeB Magnets: Known for their superior strength (up to 14,000 gauss), these rare-earth magnets are ideal for demanding applications requiring high efficiency. They offer excellent coercivity (resistance to demagnetization) and can capture even tiny ferrous particles. However, they are more expensive and sensitive to high temperatures (above 80°C), making them best for controlled environments like food processing.

- Ceramic Ferrite Magnets: More affordable and heat-resistant (up to 250°C), these provide moderate strength (around 3,000-4,000 gauss) and are suitable for general-purpose use. They have high durability in corrosive settings but are less effective against very fine contaminants compared to NdFeB.

The choice depends on the application: NdFeB for precision and high-volume lines, ferrite for cost-sensitive or high-heat scenarios. Both types are designed for long-term magnetism and easy integration into the hump housing.

Applications of Hump Magnets

Hump magnets are versatile across industries, ensuring contaminant-free products and machinery protection. Key uses include:

- Metal Cleaning and Processing: In casting, metallurgy, and machinery manufacturing, they remove iron filings, rust, and impurities from metal surfaces, improving quality in automotive or shipbuilding operations.

- Scrap Iron Recycling: Widely used in scrap steel yards and metallurgical plants to separate and recover ferrous waste like scrap metal and filings, enhancing recycling efficiency and reducing waste.

- Food Processing: Essential for separating metal contaminants from grains, powders, or liquids, ensuring food safety and compliance with standards like HACCP. For example, in flour mills or cereal production, they prevent machinery damage and product recalls.

- Pharmaceuticals and Chemicals: In drug manufacturing or chemical blending, they maintain purity by removing ferrous particles, protecting sensitive equipment and final products.

- Other Sectors: Applied in plastics recycling, mining, and even medical equipment maintenance (e.g., separating metallic debris in lab tools), though not directly in MRI systems.

Real-world examples include Eriez or Bunting Magnetics models used in global food giants like Nestlé for contaminant control.

Quick Comparison Table: NdFeB vs. Ferrite in Hump Magnets

| Magnet Type | Strength (Gauss) | Cost | Heat Resistance | Best For |

|---|---|---|---|---|

| NdFeB | 10,000-14,000 | High | Low (up to 80°C) | High-precision, fine contaminants |

| Ferrite | 3,000-4,000 | Low | High (up to 250°C) | General use, high-heat environments |

Safety Tips and Final Thoughts

For safe operation, regularly clean hump magnets (every shift in high-contaminant lines) using non-magnetic tools to avoid injury or demagnetization. Ensure proper installation to match flow rates, and monitor for wear in corrosive settings. Always consult manufacturers for custom designs.

In conclusion, hump magnets are indispensable for industrial purity and efficiency, from food safety to metal recycling. By understanding their workings and magnet options, you can optimize your processes and minimize risks. Ready to implement? Contact us tailored hump magnet solutions and elevate your production line today!

Leave a Reply