Permanent magnets play a crucial role in various industries, from automotive sensors to electric motors and audio equipment. Among the traditional permanent magnet materials, AlNiCo (Aluminum-Nickel-Cobalt) has been a staple for decades due to its excellent temperature stability. However, FeCrCo (Iron-Chromium-Cobalt) magnets have emerged as a versatile alternative, offering similar magnetic performance with enhanced machinability. In this blog post, we’ll explore the key differences between these two magnet types, their properties, and why FeCrCo is often used to replace AlNiCo in specific applications—especially where ease of processing is a priority.

What Are AlNiCo Magnets?

AlNiCo magnets, developed in the 1930s, are one of the oldest types of permanent magnets still in widespread use. They are composed primarily of aluminum (Al), nickel (Ni), cobalt (Co), and iron (Fe), with small additions of elements like copper or titanium to enhance properties.

Key Properties of AlNiCo Magnets:

- Magnetic Strength: They offer moderate magnetic field strength with high remanence (Br) but lower coercivity (Hcj), making them susceptible to demagnetization in strong external fields.

- Temperature Stability: Exceptional heat resistance, with maximum operating temperatures up to 525–550°C (975–1020°F) and a Curie temperature around 800°C. They have the lowest temperature coefficient among magnet materials (-0.02% per Kelvin).

- Corrosion Resistance: Excellent, requiring no protective coatings in most environments.

- Mechanical Properties: Brittle and hard, making them difficult to machine. They must be produced via casting or sintering and cannot undergo cold working.

- Other Characteristics: Electrically conductive, stable if handled properly, and available in isotropic or anisotropic forms.

AlNiCo magnets are ideal for high-temperature applications like aerospace sensors or guitar pickups, where their stability shines. However, their brittleness limits design flexibility.

What Are FeCrCo Magnets?

FeCrCo magnets, introduced in the 1970s, are a newer alloy designed to mimic some of the best traits of AlNiCo while addressing its shortcomings. Their composition typically includes 20–33% chromium (Cr), 3–25% cobalt (Co), and the balance iron (Fe).

Key Properties of FeCrCo Magnets:

- Magnetic Strength: Comparable to AlNiCo 5, with good remanence and energy product (BHmax). They can be magnetized with multiple poles, including planar multipole configurations.

- Temperature Stability: Strong performance up to 400°C operating temperature and a Curie temperature of about 680°C. They also exhibit good thermal stability.

- Corrosion Resistance: Excellent, similar to AlNiCo, with no need for additional protection in standard conditions.

- Mechanical Properties: Highly malleable and ductile, allowing easy machining (e.g., turning, milling, stamping, stretching) and hot deformation like wire drawing or tube rolling. This is their standout feature.

- Other Characteristics: Economical, deformable, and versatile in shapes and sizes with minimal limitations.

FeCrCo magnets are often called the “transformers” of permanent magnets due to their processing flexibility, making them suitable for custom designs in electronics or instrumentation.

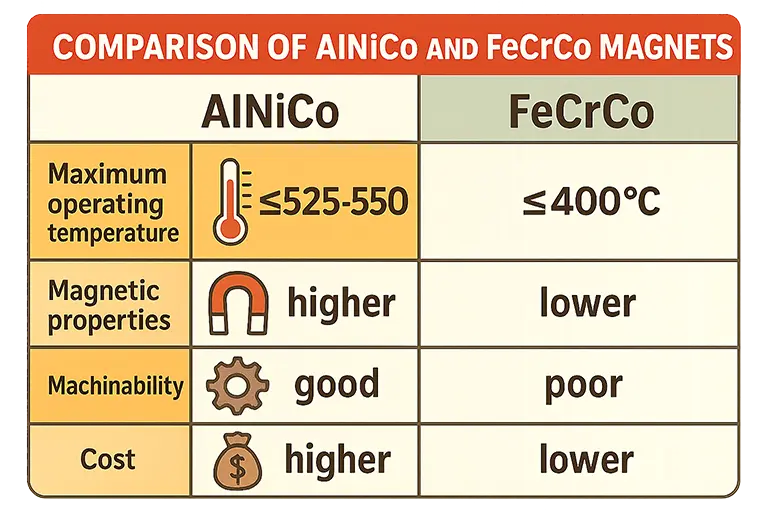

Key Differences Between FeCrCo and AlNiCo Magnets

While both magnets share similarities in magnetic performance and temperature resistance, their differences lie primarily in composition, machinability, and thermal limits. Here’s a side-by-side comparison:

| Property | AlNiCo Magnets | FeCrCo Magnets |

|---|---|---|

| Composition | Al (8-12%), Ni (15-26%), Co (5-24%), Fe (balance), plus Cu/Ti | Fe (balance), Cr (20-33%), Co (3-25%) |

| Magnetic Strength | Moderate (similar to FeCrCo), lower coercivity | Equivalent to AlNiCo 5, multi-pole capable |

| Max Operating Temp | Up to 525–550°C | Up to 400°C |

| Curie Temperature | ~800°C | ~680°C |

| Machinability | Poor (brittle, cast/sinter only) | Excellent (malleable, hot deformable, machinable) |

| Corrosion Resistance | Excellent | Excellent |

| Cost/Availability | Established, but processing limits shapes | Economical, flexible shapes |

| Typical Applications | High-heat sensors, speakers, motors | Custom machined parts, hysteresis motors, pickups |

Data compiled from various sources.

In summary, AlNiCo excels in extreme heat environments, while FeCrCo prioritizes ease of fabrication without sacrificing much magnetic performance.

Why Use FeCrCo Magnets to Replace AlNiCo?

FeCrCo is frequently chosen as a direct substitute for AlNiCo in applications where complex shapes or precise machining are required. The primary reason? Machinability. AlNiCo’s brittleness restricts it to simple forms produced by casting, often leading to higher production costs and limitations in design innovation. FeCrCo, on the other hand, can be hot deformed, drawn into wires, or machined into intricate components like threaded rods for guitar pickups—areas where AlNiCo struggles.

Other replacement advantages include:

- Shape Flexibility: No practical limits on sizes or forms, enabling small, thin, or complex designs.

- Cost Efficiency: Easier processing reduces manufacturing expenses, and it’s a viable alternative to discontinued materials like CuNiFe.

- Similar Performance: In non-extreme heat scenarios (below 400°C), FeCrCo matches AlNiCo’s magnetic output, making it a drop-in replacement for hysteresis motors, sensors, or audio speakers.

However, if your application demands temperatures above 400°C, stick with AlNiCo to avoid performance degradation.

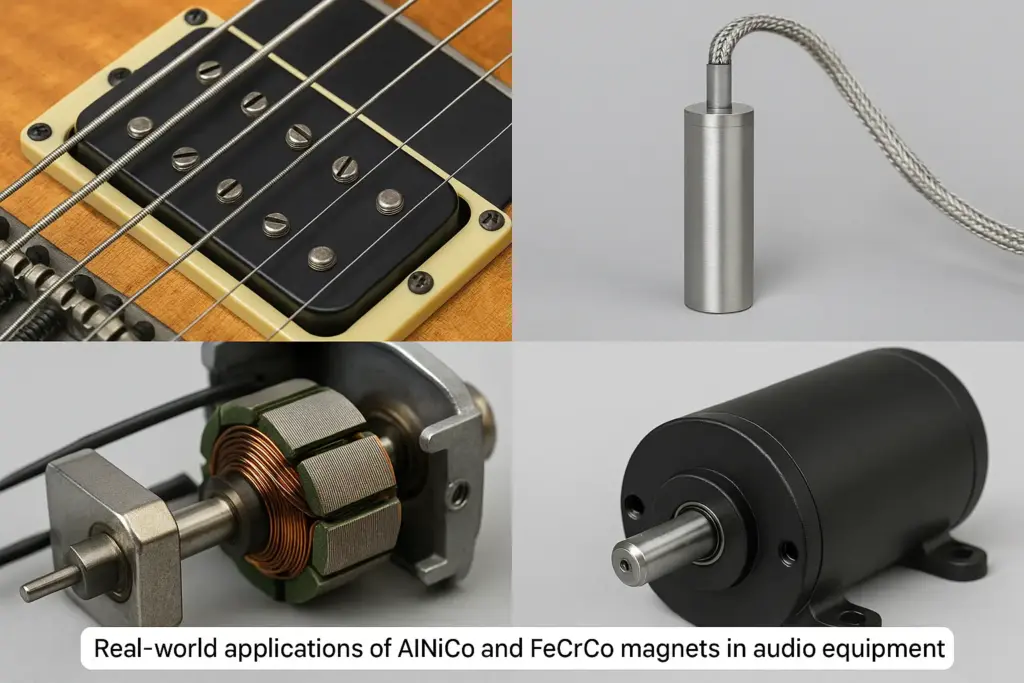

Applications and Real-World Examples

Both magnets are used in similar fields, but FeCrCo shines in customizable scenarios:

- Automotive and Sensors: FeCrCo for machined sensor components; AlNiCo for high-heat engine parts.

- Audio Equipment: FeCrCo threaded rods in guitar pickups as an AlNiCo 2 or 5 equivalent, offering similar tone with easier assembly.

- Hysteresis Motors: FeCrCo’s deformability allows for efficient production in electric motors.

- Medical and Instrumentation: FeCrCo for precise, corrosion-resistant tools.

In guitar amp communities, for instance, FeCrCo is praised as a modern substitute for vintage AlNiCo speakers, providing comparable sound with better durability.

Conclusion

FeCrCo and AlNiCo magnets both deliver reliable performance in demanding environments, but FeCrCo’s superior machinability makes it an attractive replacement for AlNiCo when design complexity or cost savings are key factors. If your project involves high temperatures without intricate shaping, AlNiCo remains a solid choice. For everything else—especially custom applications—consider switching to FeCrCo to streamline production and expand possibilities.

If you’re engineering a new product or retrofitting an old one, evaluate your temperature needs and processing requirements carefully. For more details on sourcing, check with magnet suppliers like Stanford Magnets or Eclipse Magnetics. What are your experiences with these magnets? Share in the comments below!

Leave a Reply