In the world of permanent magnets, new materials don’t appear very often. For decades, NdFeB (Neodymium Iron Boron) and SmCo (Samarium Cobalt) have dominated the high-performance magnet market. But in recent years, a promising newcomer—Samarium Iron Nitride (SmFeN)—has been gaining attention for its unique combination of high magnetic performance, corrosion resistance, and thermal stability.

SmFeN magnets are seen as one of the most exciting developments in the rare earth magnet field since the 1980s. Let’s explore their origin, how they’re made, how they compare to NdFeB, and what the future may hold.

A Brief History of SmFeN Magnets

The Sm–Fe–N magnetic compound was first studied in the late 1980s and early 1990s, when researchers discovered that introducing nitrogen into the Sm₂Fe₁₇ lattice could significantly increase its saturation magnetization and anisotropy field.

- 1980s: Sm₂Fe₁₇ compound known, but magnetic properties not competitive with NdFeB.

- 1991: Breakthrough nitrogenation process developed—leading to Sm₂Fe₁₇N₃.

- 1990s–2000s: Lab-scale synthesis proved high coercivity and good corrosion resistance.

- 2010s onward: Industrial interest grew due to Nd price volatility and demand for high-temperature magnets without heavy reliance on dysprosium.

Production Process of SmFeN Magnets

Manufacturing SmFeN magnets involves more steps than traditional NdFeB, mainly due to the nitrogenation process:

- Alloy Preparation

- Samarium and iron are alloyed (often via strip casting or gas atomization) to produce Sm₂Fe₁₇ powder.

- Nitrogenation

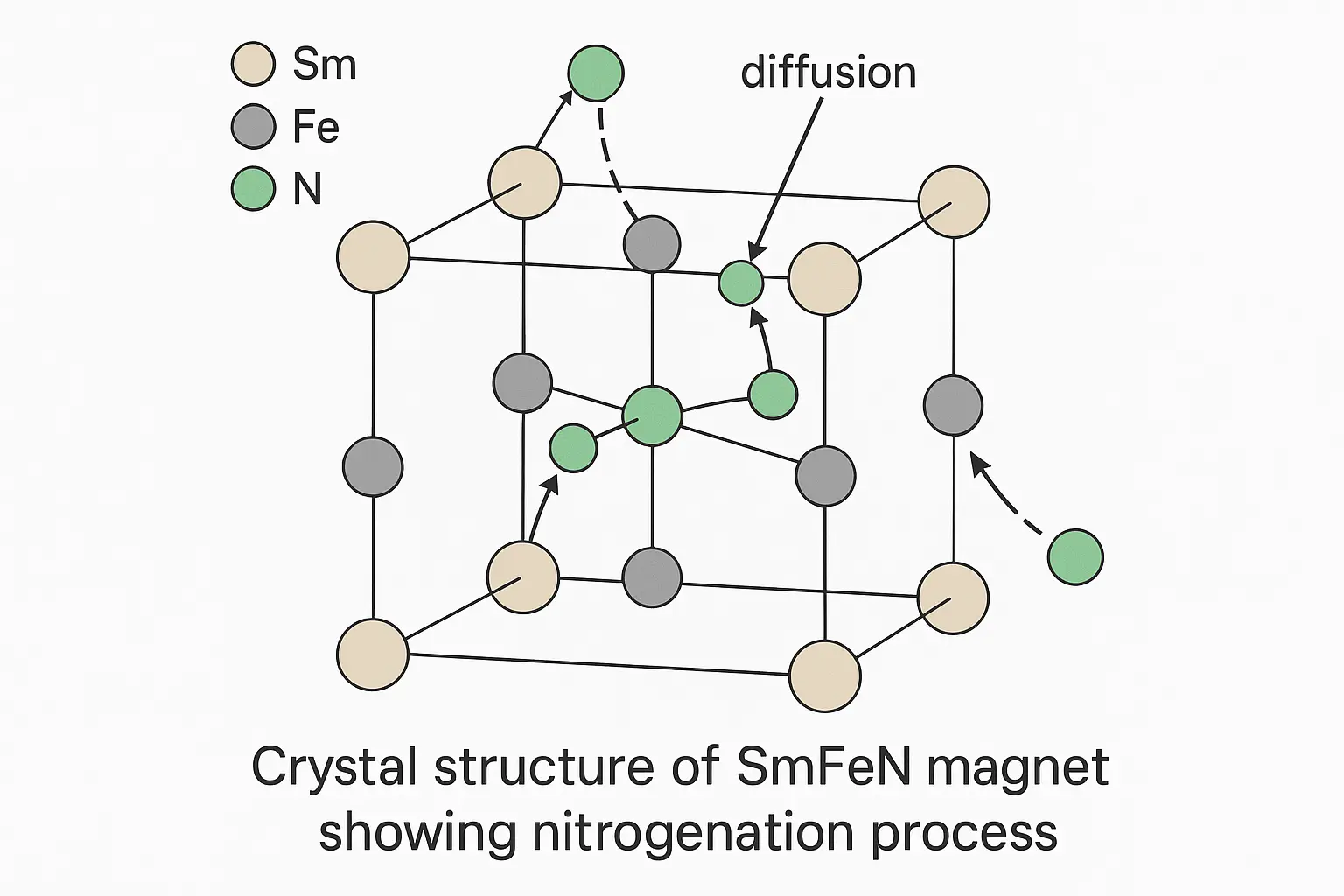

- The alloy powder is heated under high-purity nitrogen gas at around 500–600 °C.

- Nitrogen atoms diffuse into the lattice, forming Sm₂Fe₁₇Nₓ (typically x ≈ 3).

- This step enhances anisotropy and remanence without significantly reducing Curie temperature.

- Powder Handling

- Because the nitrogenated powder is prone to decomposition at high temperatures, low-temperature processing is critical.

- Magnet Formation

- Bonded magnets: SmFeN powder is mixed with polymer binders and formed via compression or injection molding.

- Sintered magnets: More challenging due to nitrogen loss during sintering; research continues to improve this step.

- Coating / Protection

- Although corrosion resistance is better than NdFeB, coatings (epoxy, PVD, etc.) are often applied for harsh environments.

SmFeN vs. NdFeB: Key Comparisons

| Property | SmFeN | NdFeB |

|---|---|---|

| Maximum Energy Product (BHmax) | ~30–40 MGOe (bonded), higher in research samples | 35–55 MGOe (sintered) |

| Temperature Stability | Excellent, retains magnetism above 200 °C | Standard grades lose strength above 80–120 °C; high-temp grades require Dy/Tb |

| Corrosion Resistance | Good, less prone to oxidation | Poor without coating |

| Raw Material Supply Risk | Samarium supply more stable; less dependence on heavy rare earths | Heavy reliance on Nd, Dy, Tb, prone to price volatility |

| Manufacturing Maturity | Emerging, still developing sintering process | Fully mature industrial production |

| Cost | Currently higher for small volumes due to limited production | Economies of scale make NdFeB cheaper |

Advantages of SmFeN Magnets

- High temperature stability without expensive dysprosium additions.

- Good corrosion resistance, even without heavy coatings.

- Stable raw material supply, especially compared to dysprosium-heavy NdFeB.

- Low eddy current loss, making them ideal for high-frequency motors.

Disadvantages

- Lower peak energy product compared to the strongest NdFeB grades (today).

- Manufacturing challenges for sintered forms due to nitrogen loss at high temperatures.

- Less mature industrial chain, meaning higher costs for now.

- Mechanical fragility in some bonded forms.

Development Trends and Future Outlook

SmFeN magnets are currently most common in bonded magnet applications, such as high-speed motors, automotive sensors, and electronics, where their stability and corrosion resistance are valued. However, the holy grail is sintered SmFeN magnets—which could rival or surpass NdFeB in certain applications without relying on heavy rare earths.

Ongoing R&D is focused on:

- Low-temperature sintering techniques to prevent nitrogen loss.

- Hybrid magnets combining SmFeN with NdFeB for balanced performance.

- Scaling production to reduce costs.

With electric vehicles, wind turbines, and high-efficiency industrial motors demanding magnets that can handle heat, corrosion, and price volatility, SmFeN could become a major player in the next decade.

Conclusion

SmFeN magnets are not just another laboratory curiosity—they represent a strategic alternative to NdFeB, especially in applications where temperature stability and supply security matter most. While production challenges remain, ongoing research and the global push for rare-earth diversification could make SmFeN magnets one of the defining magnetic materials of the future.

Leave a Reply