Usually, CNC machining center or grinding machine process, the product is required to be fixed. Previously, people were using jigs to fix the products to be processed, but this way, both in terms of safety and ease of operation, did not meet the requirements. Therefore, magnetic chucks were invented to fix products. Initially, people used electromagnetic chuck, which is mainly used to hold products by means of magnetic circuits generated by coils. But electromagnets are large, costly, and often faulty. So people invented permanent magnetic chucks.

Principle of the permanent magnetic chucks

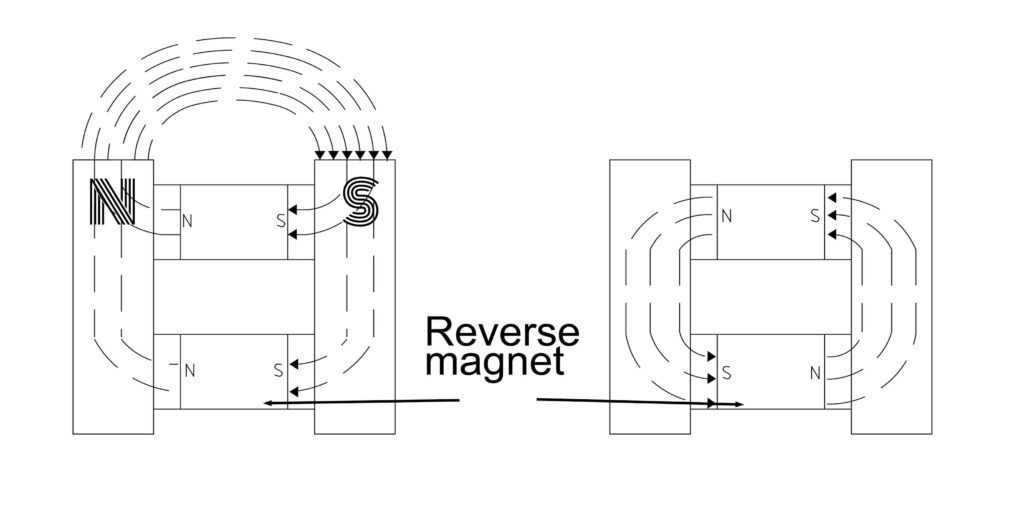

There are some differences in the design of the magnetic chucks from different manufacturers, but the principle is similar. Usually, there are several magnetic systems in the magnetic chuck module, through the relative movement of the magnetic systems, the magnetic fields on the working pole surface will add or eliminate each other, so as to achieve the purpose of sucking or unloading the processed products.

Let’s take one of the simple designs as an example to understand how magnetic chucks work. In figure 1, we can see that there is a magnetic circuit at the top of the magnetic pole at this time. This is the time when the processed product can be fixed. This is because, in this magnetic group, there are two magnetic systems that are in the same direction. Their combined force expresses the magnetic path force lines to the outside through the magnetic poles. In figure 2, we can see that the two permanent magnets, which form the circuit so that the magnetic lines of force are inside the magnetic circuit, form a few lines of force to the outside. This way the magnetic suction cup loses its hold on the external processed plant product.

Alnico Magnet used in Magnetic Chucks

Among our magnetic chuck customers, the magnets they commonly use are Alnico Class 5 magnets. As a professional manufacturer of Alnico magnets, our earliest customers we contacted were from Italy. The grade they needed was LNG44. Later we also offered LNG40 and other different grades. Here are the main magnetic suction cup magnets we offer.

Why choose Alnico 5?

Alnico magnets are characterized by particularly good temperature stability, but the magnetic properties are not particularly strong. However, in the application of magnetic chucks, the magnetic force of processed products can be fully satisfied by perfecting the design of magnetic circuit. And because Alnico 5 magnet is characterized by high remanence and relatively low coercivity. With low coercivity, it is possible to demagnetize the magnet of the circuit that needs to be reversed. And high remanence, can provide a relatively high surface magnetization. Therefore, Alnico 5 is widely used in magnetic chuchs for grinding machines.

Other magnetic materials for magnetic Chucks?

We have also met some customers who use other magnetic materials for magnetic chucks, mainly for fixing larger, heavier products. These applications are similar to magnetic lifter. But there are some differences in the design. Some customers now have designs using samarium cobalt magnet on magnetic chucks. NdFeB is commonly used in magnetic lifter, the magnetic chucks usually don’t need too strong force, but less in magnetic chucks. If you have a different design, please contact us. Our experience in magnetic materials can help you.

[row]

[col span__sm=”12″]

[ux_products type=”row” show_cat=”0″ show_rating=”0″ show_price=”0″ show_add_to_cart=”0″ show_quick_view=”0″ equalize_box=”true” ids=”2782,2772″]

[/col]

[/row]