What is Rubber Coated Magnet?

A Rubber Coated Magnet is a type of permanent magnet that has a layer of rubber covering the magnetic surface,black magnetic bases with threaded rods in the center. These are typically used in industrial or mechanical settings to securely mount or hold objects.

Key Features:

Protection of Surfaces: The rubber coating helps prevent scratches or damage to the surfaces the magnet comes in contact with, such as painted or polished metal surfaces.

Corrosion Resistance: Rubber provides protection against moisture, preventing the magnet from rusting, making it suitable for outdoor or wet environments.

Increased Friction: The rubber adds friction between the magnet and the surface it attaches to, improving grip and making it less likely to slide or shift under force.

Durability: The coating adds an extra layer of protection, making the magnet more resistant to physical impacts and wear.

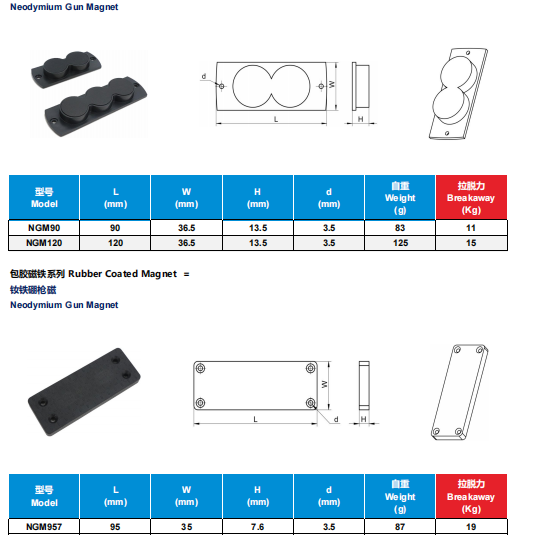

Types:

Applications:

1. Automotive Industry

Vehicle Signage: Used to attach signs, banners, or advertising displays to cars without scratching the paint.

Temporary Mounting: For securing accessories like antennas, cameras, or GPS devices to vehicles without causing damage to the bodywork.

Tool Holders: For securing tools and equipment in automotive workshops without damaging surfaces.

2. Marine Industry

Equipment Mounting: Ideal for mounting equipment like lights, antennas, or sensors on boats, yachts, or marine docks where moisture resistance is crucial.

Non-slip Applications: The rubber coating prevents sliding, which is critical in environments with constant movement, such as on boats.

3. Retail Displays and Exhibitions

Product Displays: Used to securely mount signs, banners, or shelves onto metal surfaces without damaging them.

Temporary Fixtures: Great for assembling and disassembling temporary booths or displays, as the magnets can be easily repositioned without leaving marks.

4. Construction and Engineering

Metal Cladding Installation: For holding steel or metal sheets in place temporarily during construction.

Safety Signs and Warning Lights: Mounted on steel structures like scaffolding, cranes, or machinery, offering a secure but non-permanent solution.

5. Lighting and Electronics

Mounting Lights: Frequently used to hold LED or spotlight fixtures to metal surfaces in both indoor and outdoor settings.

Electronics Enclosures: For securely mounting electronic devices or enclosures onto metallic surfaces, protecting them from environmental damage.

6. Furniture and Home Décor

Magnetic Hooks: For attaching items like kitchen utensils or office tools to metal surfaces (e.g., refrigerators or metal storage units).

Decorative Mounting: For attaching décor, such as artwork or signs, to metal walls without causing scratches or other damage.

7. Outdoor Advertising and Signage

Billboard and Sign Mounting: Rubber coated magnets are commonly used in outdoor advertising to hold signs securely, especially in conditions where weather and movement can be a concern.

Temporary Signs: Magnetic bases can hold warning or directional signs to metal surfaces without permanent attachment.

8. Sports and Leisure

Fitness Equipment: For securing attachments like phone holders or water bottles to metal surfaces on exercise machines.

Outdoor Gear: Holding equipment like tools, cameras, or gear to metal parts on vehicles, trailers, or other outdoor setups.

9. Magnetic Mounting for Cameras

Surveillance Cameras: For mounting cameras to metal surfaces, allowing for easy repositioning while preventing damage to the surface.

Action Cameras: Often used in outdoor or extreme sports for securely mounting GoPro-style cameras to vehicles or metal surfaces.

10. Manufacturing and Warehousing

Fixture Mounting: Rubber coated magnets are used in factories to hold fixtures or tools securely on workstations without scratching surfaces.

Label Holders: Can be used for attaching labels, signs, or instructions to machines or shelves in warehouses.

11. Solar Panel Installation

Temporary Mounts: Useful for temporarily attaching solar panels or equipment to metal roofs during installation and adjustments.

12. Safety and Security

Temporary Barriers: Rubber coated magnets are used to hold temporary metal barriers or fences in place during events or construction.

Security Systems: Magnetic mounting for sensors, alarms, or cameras where surface protection is essential.