Magnetizing direction plays a crucial role in determining how effectively a magnet performs in specific applications. While in some cases polarity may not matter, in many engineering and industrial uses, the magnetization orientation directly impacts performance, efficiency, and cost.

Understanding the conventional and specialized magnetization options available helps engineers, designers, and buyers make the right decision.

Table of Contents

Isotropic vs. Anisotropic Magnets

Isotropic Magnets

- Magnetic properties are the same in all directions.

- Can be magnetized in any orientation after production.

- More flexible but generally weaker than anisotropic magnets.

- Examples: Alnico 2, Alnico 3, bonded neodymium.

Anisotropic Magnets

- Have a preferred direction of magnetization.

- Stronger magnetic performance because of oriented material.

- Once magnetized, the direction cannot be changed.

- Examples: Cast Alnico 5, 6, 8; sintered neodymium; samarium cobalt.

Conventional Magnetization Directions

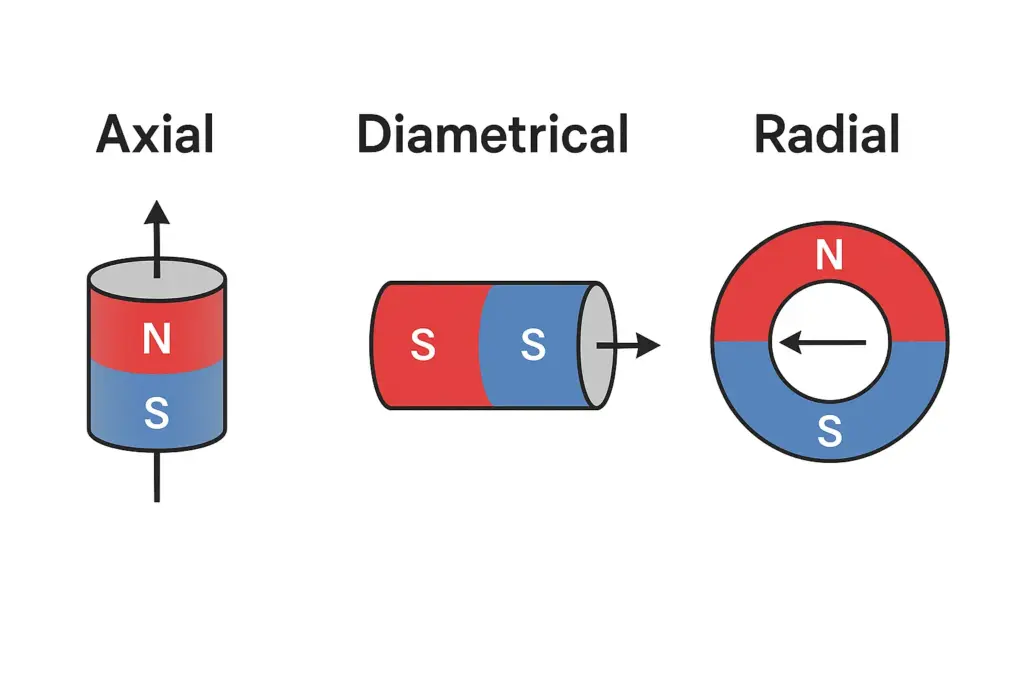

Axially Magnetized

- Magnetized through the length (for discs, cylinders, and blocks).

- Provides maximum surface holding force.

- Common in disc magnets for holding and clamping applications.

Diametrically Magnetized

- Magnetized through the diameter or width.

- Common in rod magnets and sensor applications.

Spherical Magnets

- Typically axially magnetized.

- By rotating the sphere, poles can be aligned to the desired position.

Specialized Magnetization Options

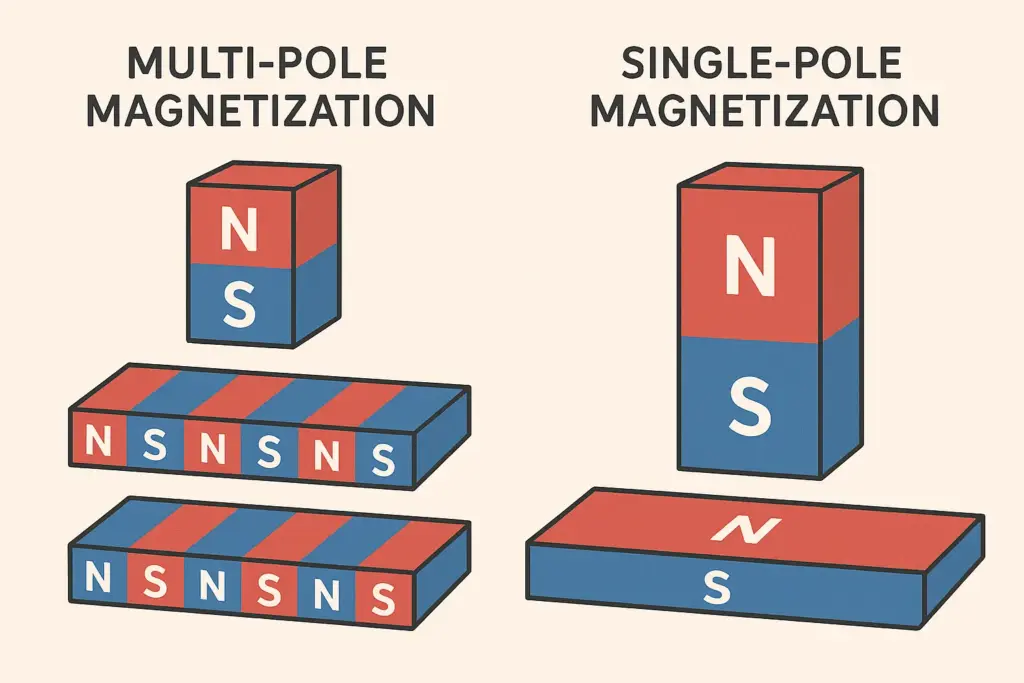

Multiple Poles

- North and South poles appear on the same surface.

- Improves holding force and shear strength.

- Common in flexible magnetic sheets, ceramic blocks, and bar magnets.

Radial Magnetization

- Magnetized from the inner to the outer diameter.

- Often used in servo motors, couplings, generators, and sensors.

- Can also be designed with multiple poles around the ring.

Arc Magnets

- Used in motors and high-performance equipment.

- True radial arcs are costly, so approximated radial or circumferential arcs are more common.

- These options balance performance with lower fabrication costs.

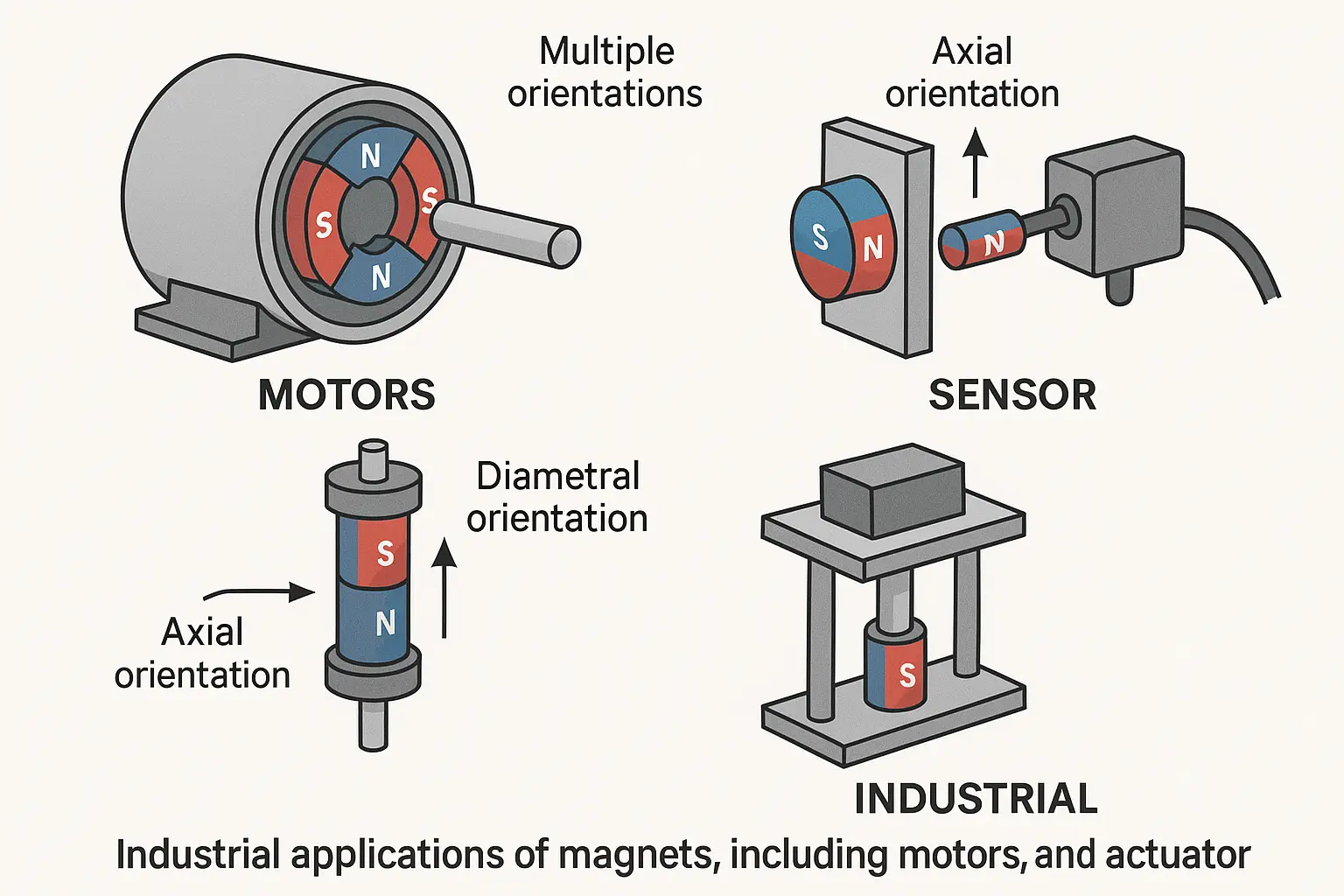

Why Magnetization Direction Matters

- Determines holding strength and performance.

- Ensures compatibility with sensors, motors, actuators, and coupling devices.

- Helps avoid unnecessary costs by selecting the most suitable orientation for the application.

Conclusion

Choosing the right magnetization direction is essential for maximizing efficiency and performance in industrial and engineering applications. Whether you need a standard axially magnetized disc or a custom radial arc, understanding isotropic and anisotropic properties is the foundation for success.

For expert advice on selecting the correct magnetization orientation, contact hsmagnet. Our professional team can provide tailored recommendations for your specific needs.

Leave a Reply