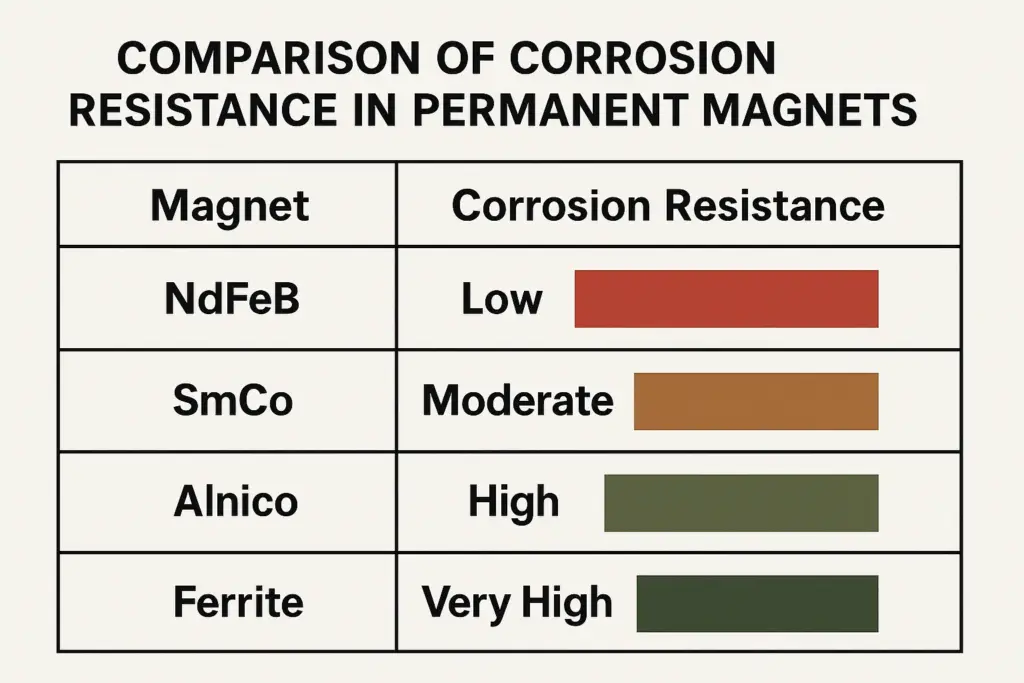

Permanent magnets are the backbone of modern industries, from medical imaging to renewable energy. However, their performance is not defined solely by magnetic strength—corrosion resistance is equally critical. Iron, the key element behind strong ferromagnetic properties, is also highly reactive with moisture, making many high-performance magnets vulnerable to degradation if not properly protected.

Neodymium Magnets: High Strength, High Corrosion Risk

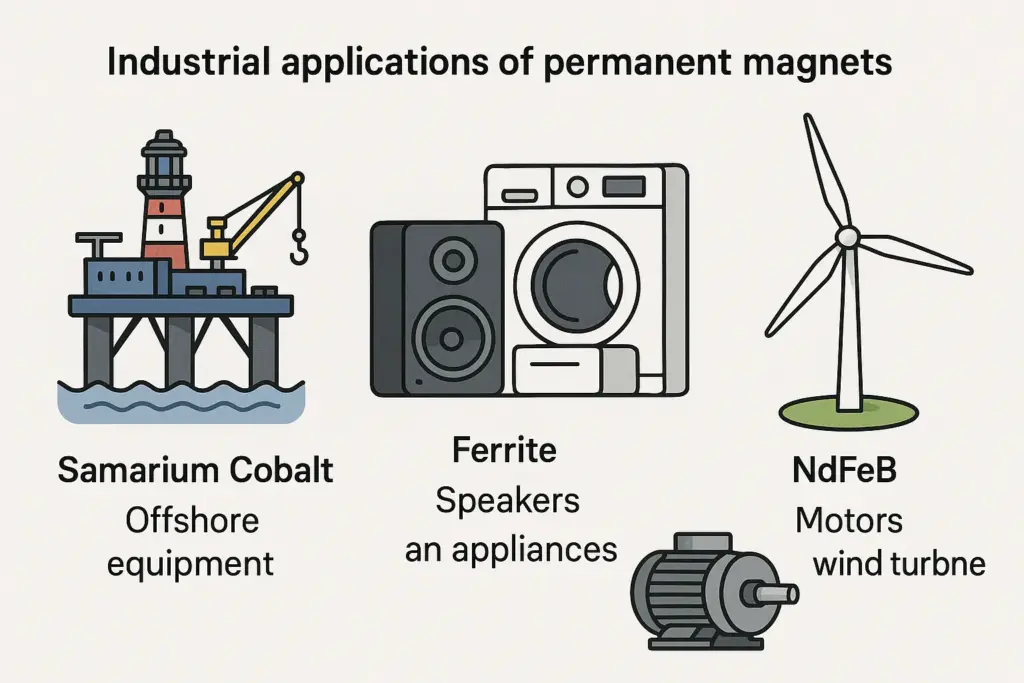

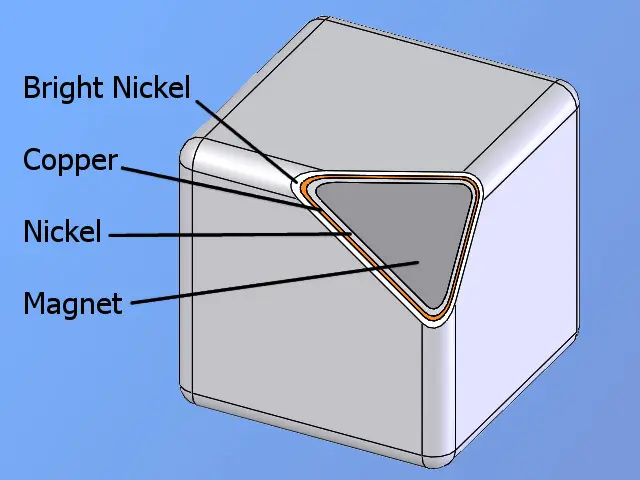

Neodymium (NdFeB) magnets deliver the strongest magnetic force available, but their 64–68% iron content makes them particularly susceptible to corrosion in damp or humid environments. To address this, manufacturers add trace elements like dysprosium to improve resistance. Almost all NdFeB magnets are coated, with the triple-layer nickel–copper–nickel system being standard. Alternative coatings—gold, silver, zinc, epoxy, or Teflon—are applied depending on end-use requirements such as durability, sterility, or aesthetics.

Samarium Cobalt Magnets: Built for Harsh Environments

Samarium Cobalt (SmCo) magnets, also part of the rare earth family, offer inherent corrosion resistance because cobalt replaces much of the iron. This makes them particularly suitable for marine, offshore, and aerospace applications, where exposure to saltwater or extreme conditions is unavoidable. Coatings are sometimes applied, but more for application-specific needs than for protection against corrosion.

Alnico Magnets: Stable and Recognizable

Alnico magnets balance durability with moderate performance. While some grades contain traces of iron that may show light surface corrosion, Alnico remains stable in contact with oils, solvents, and alcohols. Traditionally coated with red paint, Alnico magnets are instantly recognizable and are valued for their long-term stability in industrial sensors, meters, and high-temperature applications.

Ferrite Magnets: Corrosion-Proof but Lower Performance

Ferrite (Ceramic) magnets are made from iron oxide, which means they are naturally resistant to corrosion—even when submerged in water. As a result, coatings are rarely required, though dust control treatments are sometimes applied. Ferrite magnets are widely used in low-cost, high-volume applications where longevity and environmental resistance outweigh maximum magnetic strength.

Future Trends in Corrosion Protection

Advancements in coating technologies are shaping the future of magnet applications. Parylene coatings, nanocomposite barriers, and eco-friendly lacquers are being explored to provide superior protection while reducing reliance on rare earth elements. In addition, sustainability considerations are driving the development of magnets with reduced rare earth consumption, ensuring long-term supply security and cost-effectiveness.

Choosing the Right Magnet for Your Application

For industrial buyers and engineers, understanding corrosion resistance is key to ensuring long product life cycles and reduced maintenance costs.

- Neodymium: Best for maximum strength but requires protective coatings.

- Samarium Cobalt: Ideal for harsh or marine environments.

- Alnico: Reliable in specialized industrial applications.

- Ferrite: Corrosion-proof choice for cost-sensitive, mass-market uses.

Selecting the right permanent magnet is not only a technical decision—it is a strategic investment in operational efficiency, durability, and performance.

Leave a Reply