A cross belt separator is an advanced, self-cleaning magnetic separator designed to remove ferrous contaminants, such as tramp metals (e.g., nuts, bolts, and scrap), from materials on conveyor belts. Ideal for industries like mining, recycling, and aggregates, these systems ensure continuous, efficient separation with minimal maintenance. Featuring high-strength magnets and a durable toothed belt, cross belt separators transport contaminants to a collection bin, protecting equipment and improving product purity.

How Does a Cross Belt Separator Work?

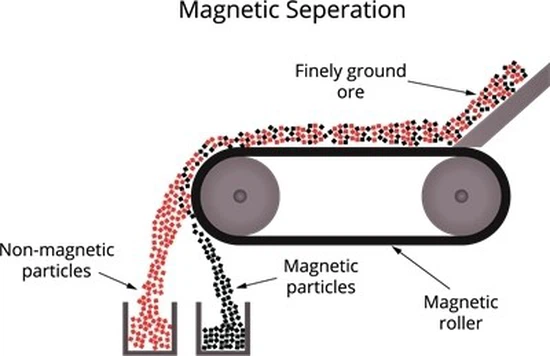

Cross belt separators operate using electromagnetism to separate ferrous materials from non-ferrous ones. The system consists of a conveyor belt with an electromagnetic coil positioned above it, generating a powerful magnetic field.

Here’s the process:

- Material Flow: Materials pass under the separator on a conveyor belt.

- Magnetic Attraction: The electromagnetic coil, powered by a rectifier converting AC to DC, creates a magnetic field that attracts ferrous particles.

- Separation: Captured ferrous materials are pulled from the material stream and transported by a toothed belt to a collection bin.

- Continuous Operation: Non-magnetic materials continue along the conveyor, ensuring uninterrupted processing.

This efficient mechanism ensures high throughput and reliable separation in demanding environments.

Types of Magnets Used in Cross Belt Separators

Cross belt separators rely on powerful magnets to capture ferrous contaminants. The two primary types are:

- Ceramic Magnets (Ferrite): Affordable and reliable, generating magnetic fields of 0.5–1 Tesla. Ideal for less demanding applications.

- Rare Earth Magnets: Including Neodymium (NdFeB) and Samarium Cobalt, these magnets produce fields exceeding 1.4 Tesla. Known for their strength, they’re brittle and coated to prevent corrosion.

Rare earth magnets, developed in the 1970s and 1980s, offer superior performance for heavy-duty applications, ensuring effective removal of even small ferrous particles.

Applications of Cross Belt Separators

Cross belt separators are versatile, serving multiple industries:

- Mining: Removes tramp metals like bucket teeth and rebar, protecting conveyor belts, pumps, and hydrocyclones.

- Aggregates: Extracts metal scraps and tools from crushed rock, ensuring product quality.

- Wood Processing: Protects chippers by removing wires and tools from wood streams.

- Biomass: Ensures metal-free wood pellets and safeguards equipment from damage.

- Recycling: Prevents metal contamination in recycled products and protects comminution equipment.

These applications enhance operational efficiency, reduce downtime, and ensure high-quality outputs.

Why Choose Cross Belt Separators?

Cross belt separators are essential for industries requiring reliable tramp metal removal. Their self-cleaning design, powerful magnets, and robust construction make them a cost-effective solution for protecting equipment and ensuring product purity. By integrating these systems, businesses can boost productivity and minimize costly repairs.

Ready to enhance your operations? Explore cross belt separator solutions tailored to your industry needs in 2025.

Leave a Reply