In the world of permanent magnets, Alnico magnets stand out for their durability, high-temperature performance, and historical significance—they were among the first permanent magnets developed in the early 20th century. Composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co), with additions like iron, copper, and titanium, Alnico magnets are prized in applications such as sensors, motors, and instruments where stability under extreme conditions is crucial. But not all Alnico magnets are created equal. In this blog post, we’ll dive into the manufacturing process of sintered Alnico magnets, explain how they’re produced, and highlight the differences from their cast counterparts. We’ll also compare Alnico to other popular permanent magnet materials like NdFeB (neodymium), SmCo (samarium cobalt), and ferrite to help you choose the right one for your needs.

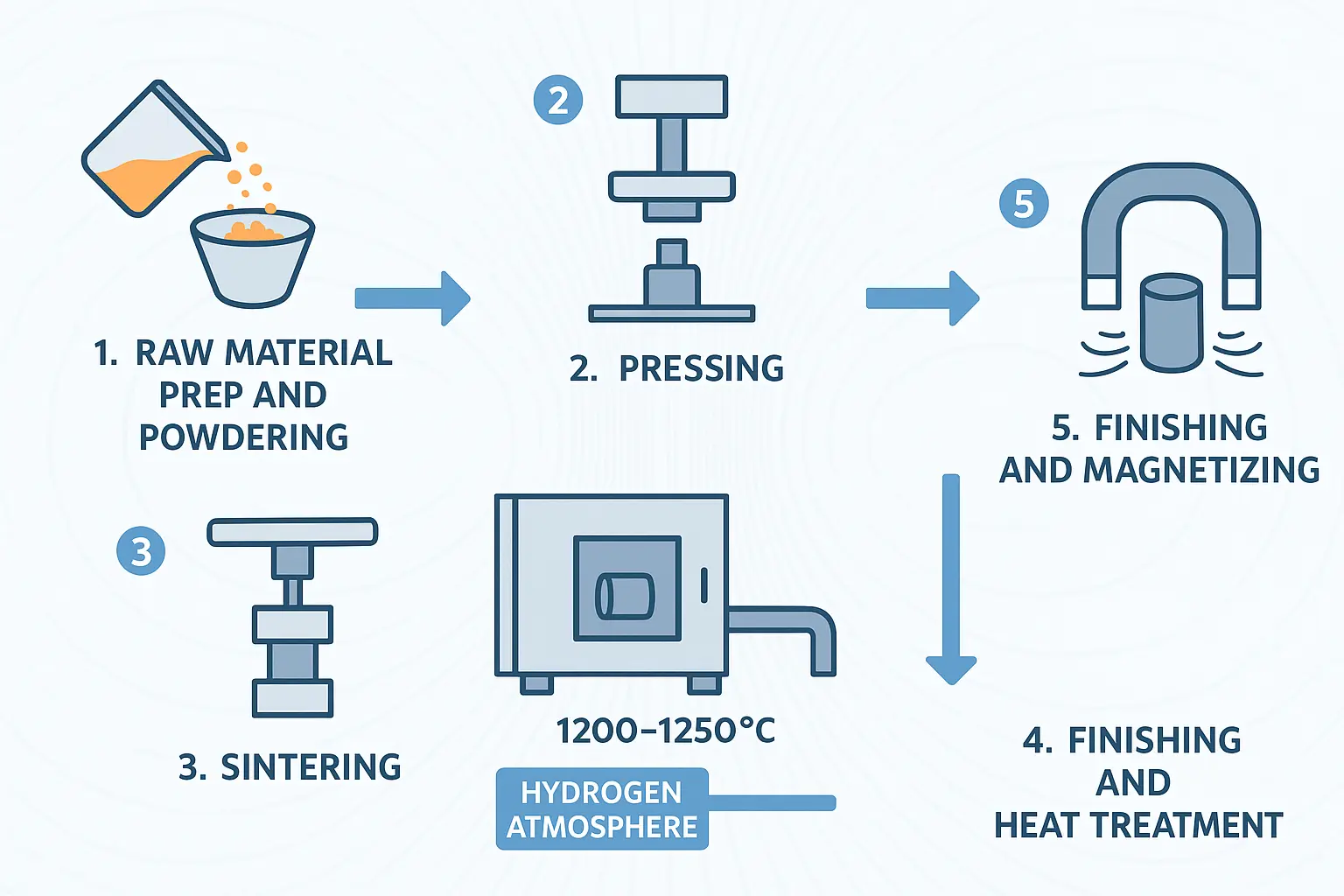

The Manufacturing Process of Sintered Alnico Magnets

Sintered Alnico magnets are produced using a powder metallurgy technique, which allows for precise shapes and efficient production, especially for smaller or complex components. This process is ideal for high-volume manufacturing and results in magnets with excellent mechanical strength. Here’s a step-by-step breakdown:

- Raw Material Preparation and Powdering: The process begins with selecting high-purity raw materials—aluminum, nickel, cobalt, iron, and other additives. These elements are melted together to form an alloy, which is then ground into a fine powder. The powder particles are typically very small to ensure uniform mixing and optimal magnetic properties.

- Pressing: The powdered alloy is mixed thoroughly and pressed into a die under high pressure. This compaction creates a “green” compact that’s close to the final desired shape and size. The die is designed to account for any shrinkage during later steps.

- Sintering: The compacted powder is heated in a furnace at temperatures around 1200–1250°C (over 2200°F) in a controlled hydrogen atmosphere. This fuses the particles together without fully melting them, creating a solid magnet. Sintering enhances density and mechanical integrity while preserving the material’s microstructure.

- Cooling and Heat Treatment: After sintering, the magnets are cooled slowly to room temperature. Additional heat treatments may be applied to optimize magnetic properties, such as stabilizing the microstructure for better coercivity (resistance to demagnetization).

- Finishing and Magnetization: The sintered pieces are machined or ground to achieve precise dimensions and surface finishes. Finally, they’re magnetized by exposing them to a strong magnetic field, aligning the domains for permanent magnetism. Coatings may be added for corrosion protection if needed, though Alnico is naturally resistant.

This process makes sintered Alnico magnets suitable for intricate designs, like those used in automotive sensors or medical devices, where precision is key.

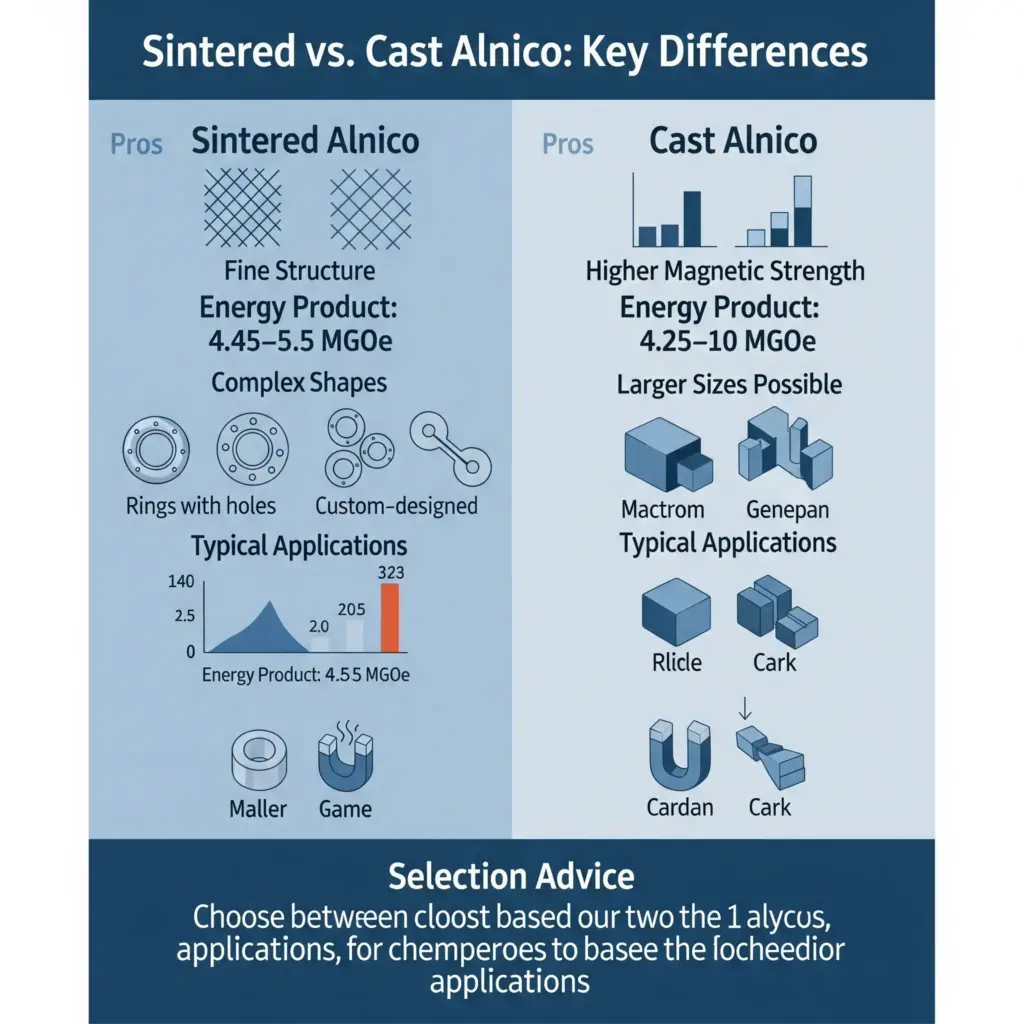

Differences Between Sintered and Cast Alnico Magnets

While both sintered and cast Alnico magnets share the same base composition, their manufacturing methods lead to distinct characteristics. Cast Alnico magnets are made by melting the alloy and pouring it into molds (often sand-based), followed by cooling and magnetization. Here’s how they compare:

| Aspect | Sintered Alnico | Cast Alnico |

|---|---|---|

| Magnetic Strength | Slightly lower (e.g., max energy product 4.45–5.5 MGOe for anisotropic grades) | Higher (e.g., 4.25–10 MGOe for anisotropic grades) |

| Mechanical Properties | Better strength, finer grain structure, higher tolerance for complex shapes | More brittle, suited for larger, simpler shapes |

| Production Suitability | Ideal for small sizes, high volumes, tight tolerances | Better for large or custom shapes, but less precise |

| Cost and Efficiency | More economical for mass production | Higher cost due to foundry process, but stronger performance |

| Anisotropy | Mostly isotropic (uniform magnetism in all directions); can be anisotropic | Often anisotropic (stronger in one direction) for enhanced performance |

In summary, choose sintered Alnico for applications needing durability and precision, like electronics, while cast versions excel in high-strength scenarios such as electric motors.

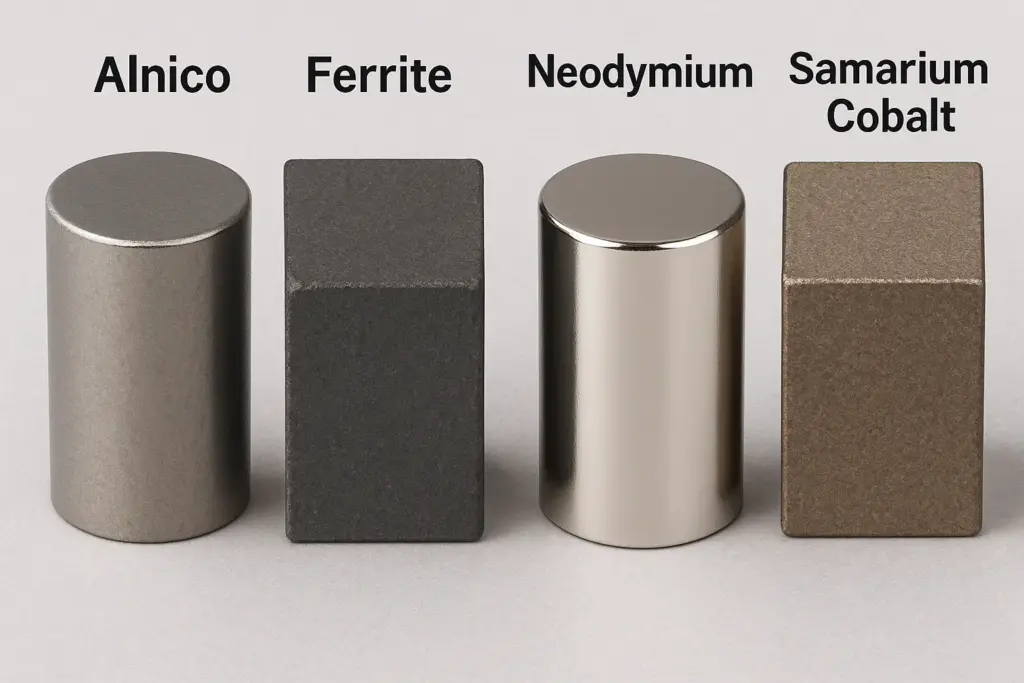

How Alnico Stacks Up Against Other Permanent Magnets

Alnico magnets aren’t the only option in the permanent magnet family. Let’s compare them to NdFeB, SmCo, and ferrite magnets across key factors to give you a clearer picture:

| Property | Alnico | NdFeB (Neodymium) | SmCo (Samarium Cobalt) | Ferrite (Ceramic) |

|---|---|---|---|---|

| Magnetic Strength (Energy Product) | Moderate (1–10 MGOe) | Highest (up to 52 MGOe) | High (15–32 MGOe) | Low (1–4.5 MGOe) |

| Temperature Resistance | Excellent (up to 500–550°C) | Low (80–200°C; curie temp ~310°C) | High (250–350°C) | Moderate (up to 250°C) |

| Corrosion Resistance | Good (no coating needed) | Poor (requires protective coatings) | Good | Excellent |

| Cost | Moderate | Moderate to high | High (due to rare elements) | Low |

| Brittleness/Durability | Moderate (cast more brittle than sintered) | Brittle | Very brittle | Brittle but stable |

| Common Applications | Sensors, guitars, high-temp environments | Motors, electronics, EVs | Aerospace, military | Speakers, toys, low-cost devices |

Alnico shines in high-heat scenarios where other magnets would fail, but it has lower coercivity, making it easier to demagnetize than NdFeB or SmCo. For instance, if you’re building electric vehicle components, NdFeB’s superior strength might win out, but for oil and gas sensors in hot environments, Alnico is unbeatable.

Conclusion

Sintered Alnico magnets offer a reliable, precise manufacturing process that balances performance with practicality, making them a go-to choice for many industries. By understanding their production and how they differ from cast Alnico or other materials like NdFeB, SmCo, and ferrite, you can make informed decisions for your projects. If you’re sourcing magnets or need custom solutions, reach out to our team—we’re here to help demystify the options and deliver quality results. Stay magnetic!

Leave a Reply