Permanent magnets, like those in speakers, motors, and fridge magnets, can retain their magnetism for decades—sometimes even centuries. But how do they resist demagnetization so effectively? The answer lies in their material composition, atomic structure, and resistance to external forces.

1. High Coercivity – Resistance to Demagnetization

Coercivity measures how well a magnet resists losing its magnetism when exposed to an opposing magnetic field. Permanent magnets (e.g., neodymium, ferrite, alnico) have extremely high coercivity, meaning they need a strong reverse field to demagnetize them.

Example: Neodymium magnets (NdFeB) have coercivity exceeding 1000 kA/m, making them nearly immune to everyday magnetic interference.

Weaker magnets (like soft iron) lose magnetism easily because they have low coercivity.

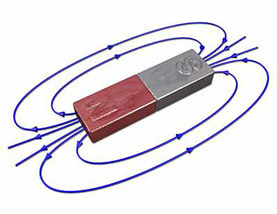

2. Stable Magnetic Domains – Locked-In Alignment

Inside a permanent magnet, tiny regions called magnetic domains align uniformly during magnetization. Due to high magnetic anisotropy (directional dependence), these domains stay locked in place.

Example: Samarium-cobalt (SmCo) magnets have a strong crystalline structure that prevents domains from flipping randomly.

Weaker magnets have domains that easily misalign under stress or heat.

3. High Curie Temperature – Heat Resistance

The Curie temperature is the point at which a magnet loses its magnetism due to thermal agitation. Permanent magnets have high Curie temperatures, far above room temperature:

Magnet Type Curie Temperature

Neodymium (NdFeB) 310°C (590°F)

Ferrite 450°C (842°F)

Alnico 750–860°C (1382–1580°F)

4. Optimized Microstructure – Preventing Domain Shifts

Modern permanent magnets are engineered with:

Fine-grained crystals – Limits domain wall movement.

Isolation phases – Acts as “pinning sites” to block demagnetization.

Example: Neodymium magnets contain Nd₂Fe₁₄B hard magnetic phases surrounded by a neodymium-rich grain boundary, enhancing stability.

5. Environmental Resistance – Avoiding Corrosion & Damage

While permanent magnets are durable, they can degrade due to:

Oxidation/Rust – Neodymium magnets corrode easily (nickel plating helps).

Physical Damage – Cracks or chips can weaken magnetism.

Strong Reverse Fields – Placing opposite poles together can demagnetize them.

If you have any questions about magnets that you would like to discuss with me or need to purchase magnets, please contact us.