What is Electropermanent magnet?

An electropermanent magnet or EPM is a type of permanent magnet in which the external magnetic field can be switched on or off by pulses of current in a winding of wire around the magnet portion. The magnet consists of two parts, one of a “hard” (high coercivity) magnetic material and the other of a “soft” (low coercivity) material. The direction of magnetization of the latter part can be switched by pulses of current in a winding of wire around the former. When the magnetically soft and hard materials have opposite magnetizations, the magnet produces no net external field at its poles, but when their magnetizations are aligned, the magnet produces an external magnetic field.

Before the invention of electropermanent magnets, applications requiring a controllable magnetic field required electromagnets, which consume large amounts of power when in operation. Electropermanent magnets do not require a power source to maintain the magnetic field. Electropermanent magnets made from powerful rare earth magnets are used as industrial lifting (pulling) magnets to lift heavy ferrous metal objects; when the object reaches its destination, the magnet can be turned off, releasing the object. Programmable magnets have also been studied as a means of creating self-building structures.

Description of Electropermanent magnet

An electropermanent magnet is a special configuration of magnetic material that can be turned on and off by applying a current pulse. The EPM is based on a common magnetic configuration called a magnetic latch. A general example of such a configuration component is built from a permanent magnet block with two plates of soft magnetic material (usually an iron alloy) on each side of the block. The two plates exceed the size of the permanent magnet. Because the plates have a higher magnetic permeability than air, they concentrate the magnetic flux of the permanent magnet. When a third (external) soft magnetic plate is placed in contact with the other two magnetic plates, the magnetic flux will be restricted to flow in the soft magnetic plates, forming a closed magnetic circuit, and the magnetic field generated by the magnet will be maximum (approximately magnetic remanence).

An EPM has at least two permanent magnets between the plates. The magnetic field generated by the EPM is generated by permanent magnets, not by current, which is the main difference from electromagnets. The EPM uses only a current pulse to magnetize one of the magnets in the desired direction (turning the external magnetic field of the latch on and off). After changing the direction of the magnet, no current is needed and the magnetic field returns to depending on the permanent magnet.

Principle of Electropermanent magnet

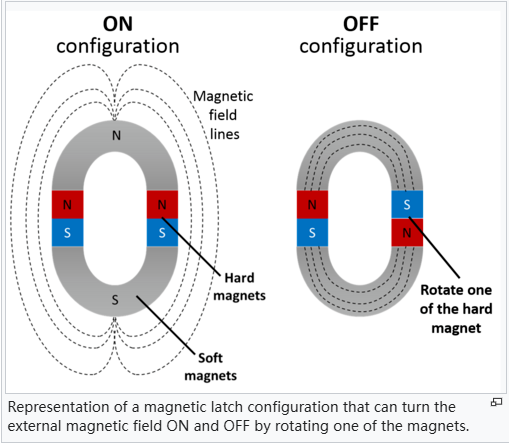

In order to explain the principle of the EPM, the configuration on the following picture is presented. Two permanent magnets are assembled with two U-shape (horseshoe) iron bars. If the north pole of both magnets are pointing up we will have the configuration described on the left: The iron U in the top will see two norths on its ends and will concentrate the flux lines but it won’t be able to contain the magnetic flux and the flux will flow through the air and will try to find the other iron U. In a general schema, the iron U on top will become a north pole of the big magnet and the bottom iron U will become a south pole. In this configuration we can say there is big magnet ON.

If we rotate one of the hard magnets (north pole point down), the iron U on top will see a north pole and a south pole. The other iron U will see exactly the opposite. In this way almost all the magnetic flux will be concentrated inside both iron U’s creating a close circuit for the magnetic field (because the high permeability of the iron). Having all the flux confined inside the structure, the magnetic flux outside became almost nonexistent. In this configuration we can say the big magnet is OFF.

Now we can move forward and instead of mechanically rotating one of the magnets we can flip the direction of its magnetization. To do it we can build the configuration on the following picture:

A coil is wound around one of the magnets in a way that if we inject enough current (in a pulse) in the solenoid the generated magnetic field inside will be higher than the intrinsic coercivity of the magnet (Hci). If this is the case the permanent magnet will be magnetized in the direction of the field inside the solenoid. Applying the same pulse of current in the opposite direction will lead to magnetize the magnet in the opposite direction. Therefore, we have the same behavior as when we mechanically rotate the magnet. This configuration is the concept of electropermanent magnet: Using a pulse of current we reverse the magnetization direction of one of the magnets and we will turn ON and OFF the external magnetic field.

It is important to mention that both magnets can be wound in the same coil, but it is necessary that one of the magnets have much lower intrinsic coercivity than the other in order to flip their magnetization direction without changing the other’s direction of magnetization. During this explanation we use one magnet made of NdFeB and the other made of AlNiCo because both materials had the same remanence (around 1.3T) but AlNiCo has a lower intrinsic coercivity of 50kA/m while NdFeB has an intrinsic coercivity of 1120kA/m.