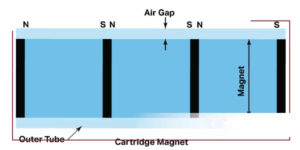

The air gap affects magnet selection, the air gap refers to the air separation between two magnetic components in a magnetic circuit, but is not limited to empty space; it may be composed of various non-magnetic materials, such as wood, plastic, or even coatings such as rubber or nickel. The presence of an air gap increases the magnetic resistance of the magnetic circuit, thereby reducing the effective magnetic force felt by the magnet. The larger the air gap, the more significant this reduction is.

In scenarios involving magnetic applications, the air gap affects magnet selection a lot, as follows:

Air gap affects magnet type selection

- Ferrite magnet: it has low cost and relatively weak magnetism. They are suitable for situations where the air gap is small and the magnetic field strength is not particularly high. For example, in some small toy motors, the air gap is usually small, and ferrite magnets can meet their basic magnetic field requirements while controlling costs.

- NdFeB magnet: It has the characteristics of high remanence, high coercivity and high magnetic energy product, and its magnetism is very strong. In the case of a large air gap, if a strong magnetic field needs to be generated, NdFeB magnets are a good choice. Like magnetic resonance imaging (MRI) equipment, NdFeB magnets are widely used due to the large internal air gap and the need for a strong and uniform magnetic field.

- Alnico magnet: it has good temperature stability and can maintain good magnetic properties in high temperature environments. If there is an air gap in the application and the operating temperature is high, Alnico magnets may be a suitable choice. For example, in magnetic sensors in some high-temperature industrial equipment, alnico magnets can work stably.

Effects on magnet size and shape selection

- Size effect: The larger the air gap, the larger the size of the magnet usually required in order to generate a magnetic field of sufficient strength and uniformity in the air gap. This is because as the air gap increases, the attenuation of the magnetic field in the air will increase. Only by increasing the volume of the magnet and providing more magnetic flux can the magnetic field in the air gap meet the requirements.

- Shape influence: Different air gap shapes and distributions require magnets to have corresponding appropriate shapes to optimize magnetic field distribution. For example, in some special magnetic circuit designs, the air gap may take on a complex shape, which requires the magnets to be processed into specific shapes, such as arcs, rings, etc., to better adapt to the requirements of the air gap and improve the magnetic field. utilization rate.

Impact on magnet performance parameter requirements

- Magnetic field strength: The existence of the air gap will weaken the magnetic field strength. The larger the air gap, the more obvious the attenuation of the magnetic field strength will be. In order to obtain the required magnetic field strength in the air gap, it is necessary to select a magnet with a higher magnetic induction intensity.

- Magnetic permeability: Magnetic permeability indicates the material’s ability to conduct magnetic fields. In air-gap magnetic circuits, magnetic permeability has an important influence on magnetic field distribution and intensity. Choosing magnet materials with higher magnetic permeability can make the magnetic field pass through the magnetic circuit more concentratedly and reduce the loss in the air gap, thus improving the efficiency of the magnetic circuit.

- Coercivity: Coercivity is a measure of a magnet’s ability to resist demagnetization. In the presence of an air gap, interference from the external magnetic field or changes in the magnetic circuit may cause the magnet to be affected by demagnetization. Therefore, for situations where the air gap is large or the working environment is complex, magnets with higher coercivity need to be selected to ensure that the magnets can maintain stable magnetism during long-term use.