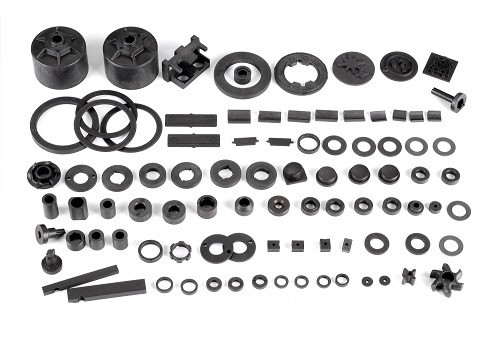

Injection Molded Magnet

Injection molded magnets are essentially made of fully dense magnetic powders with a variety of polymer base materials. Injection molding is a great choice for creating customized, injection molded magnets that can be used in many different types of products because it yields strong magnet strength and efficient magnetic field distribution. Injection molding also allows for excellent control over part size and shape as well as surface finish and metal fin end use requirements like corrosion resistance. In some cases Injection Molded Magnets can be used in place of steel components which saves on manufacturing cost while providing an exceptional weight-to-strength ratio that’s superior to many other options.