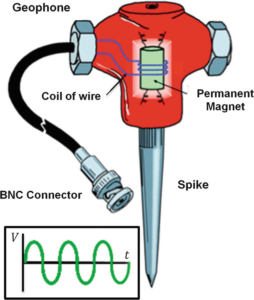

A geophone is a highly sensitive ground motion transducer that converts ground movement (velocity) into voltage, which may be recorded at a recording station. The deviation of this measured voltage from the baseline is called the seismic response and is analyzed for the structure of the earth, which has been used by seismologists and geophysicists for decades.

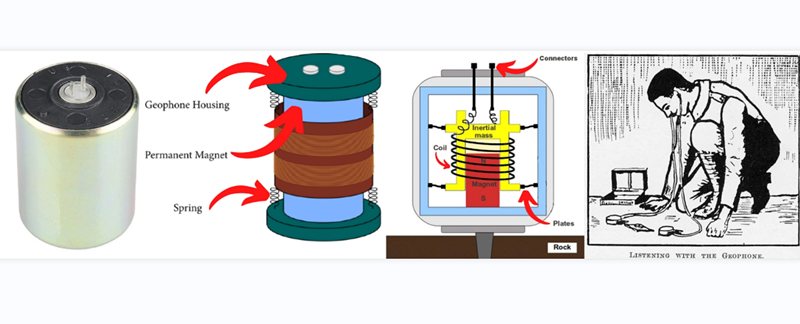

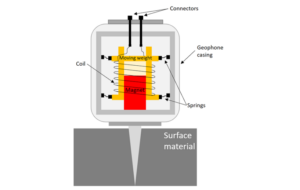

Geophones have historically been passive analog devices and are employed to monitor velocity, typically consisting of a magnetic core, surrounded by an electric coil, moving within the field of a case-mounted permanent magnet to generate an electrical signal. As the ground vibrates, the housing moves but the coil tends to stay stationary. The movement of the magnet within the coil induces an electrical current that is calibrated to the velocity of vibration.

An important feature of geophones is that they can only monitor frequencies above their natural frequency, up to a specified spurious frequency. A natural frequency on the order of 10 Hz, and a spurious frequency on the order of 250 Hz are common. This frequency range precludes using geophones for certain applications, such as monitoring pile driving. Nevertheless, geophones are one of the most common sensors employed for monitoring blasting and construction activities.

Different geophones

There are three types of common geophones: vertical, horizontal, and multi-component. And these can have different frequencies. Typically, we use vertical geophones for refraction and surface wave studies and horizontal geophones for reflection, and multi-component for some advanced studies of ground motion.

Geophone frequencies

The choice of geophone frequency will depend upon the type of seismic investigation being undertaken and the application. Surface wave methods must use low-frequency geophones below 5 Hz, while refraction typically uses 10-28 Hz geophones and reflection surveys will normally use 10-40 Hz geophones. High-frequency ratings on the geophone give greater resolution but limit the depth/distance that the seismic energy will be detected.

Frequency rating of a geophone

Geophones have a “resonant frequency” – this is the frequency of vibration at which they prefer to oscillate and therefore give the biggest response. Low-frequency geophones are good at detecting low-frequency vibrations and these are the ones that travel deep and far. A higher-frequency geophone will respond best to faster oscillations which are the ones that create more detail. For ground vibrations at frequencies on either side of the resonance rating, a geophone will record those above the rating better than those below so, if in doubt, it is better to use a geophone with too low frequency than too high.

Horizontal geophones for reflection surveys

Although reflection surveys can be undertaken with vertical geophones, for a near-surface survey we recommend horizontal units because:

They minimize the effects of refracted waves.

Random noise tends to be dominated by P-wave motion.

Shear wave velocities can help differentiate between similar VP velocities.

They will be measuring shear movement and S-waves travel slower, equating to shorter wavelengths and thus better resolution.

Using the same geophone for refraction, reflection, and surface wave methods

Under specific circumstances, you can use the same geophone for all three different types of investigations, but your data would be compromised.

The 4.5 Hz vertical geophones used in surface wave studies could be used to collect refraction and reflection data, but the resolution would be reduced. This will be a bigger problem for reflection investigations where the aim of the survey may be to map stratigraphy in detail.

And compromising on the use of a single geophone will not work the other way round: in other words, higher frequency geophones – suited to good quality refraction and/or reflection work – will not be appropriate for surface wave surveys, as these require frequencies below 5 Hz.

3-component (3C) geophone

Regular geophones have a single sensor in them which is orientated to be sensitive to either horizontal motion or vertical motion. A 3-component geophone has three sensors inside – one mounted vertically and two mounted horizontally at 90° to each other (to measure ‘left-right’ and ‘forward-backward’ horizontal motion). These are commonly used for HVSR (Horizontal-to-Vertical Spectral Ratio) surface wave studies and monitoring projects.

Omnidirectional geophone

An omnidirectional geophone is a single geophone sensor that will operate equally well regardless of its orientation (right way up, sideways, upside down, at an angle).

To achieve high sensitivity, the mass of the magnet is large, which unfavorably influences the coupling at high frequencies between the geophone and the ground in which it is implanted. Different types of permanent magnets will offer different features to geophones.

AlNiCo magnets, Samarium Cobalt magnets, and Neodymium magnets were all used to geophones, but AlNiCo magnets are still regarded as the most suitable selection of geophone magnets due to their high accuracy, stability and cost-effective.