Description

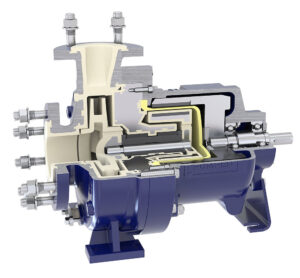

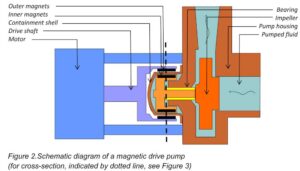

A magnetic pump consists of three parts: a pump, a magnetic actuator, and an electric motor. The key component of the magnetic actuator is composed of an external magnetic rotor, an internal magnetic rotor, and a nonmagnetic isolation sleeve. When the electric motor drives the outer magnetic rotor to rotate, the magnetic field can penetrate the air gap and nonmagnetic substances, driving the inner magnetic rotor connected to the impeller to rotate synchronously, achieving contactless transmission of power and converting the dynamic seal into a static seal. Due to the complete closure of the pump shaft and inner magnetic rotor by the pump body and isolation sleeve, the problem of “running, emitting, dripping, and leaking” has been completely solved, eliminating the safety hazards of flammable, explosive, toxic, and harmful media leaking through the pump seal in the refining and chemical industry, effectively ensuring the physical and mental health of employees and safe production.

Working principle

Arrange and assemble n pairs of magnets (n is an even number) on the inner and outer magnetic rotors of the magnetic drive according to the rules, so that the magnet parts form a completely coupled magnetic system with each other. When the inner and outer magnetic poles are opposite to each other, that is, the displacement angle between the two magnetic poles Φ=0, the magnetic energy of the magnetic system is the lowest at this time; when the magnetic poles rotate to the same polarity, that is, the displacement angle between the two magnetic poles Φ=2π /n, the magnetic energy of the magnetic system is maximum at this time. After the external force is removed, the magnetic force will restore the magnet to the state with the lowest magnetic energy due to the mutual repulsion of the magnetic poles of the magnetic system. Then the magnet moves, driving the magnetic rotor to rotate.

Advantages

Compared with traditional centrifugal pumps that use mechanical seals or packing seals, magnetic pumps have the following advantages:

- The pump shaft has changed from a dynamic seal to a closed static seal, completely avoiding medium leakage.

- No need for independent lubrication and cooling water, reducing energy consumption.

- Transforming from coupling transmission to synchronous driving, without contact or friction. Low power consumption, high efficiency, and damping effect reduce the impact of motor vibration on the pump and the impact of pump cavitation vibration on the motor.

- When overloaded, the inner and outer magnetic rotors slip relatively, providing protection for the motor and pump.