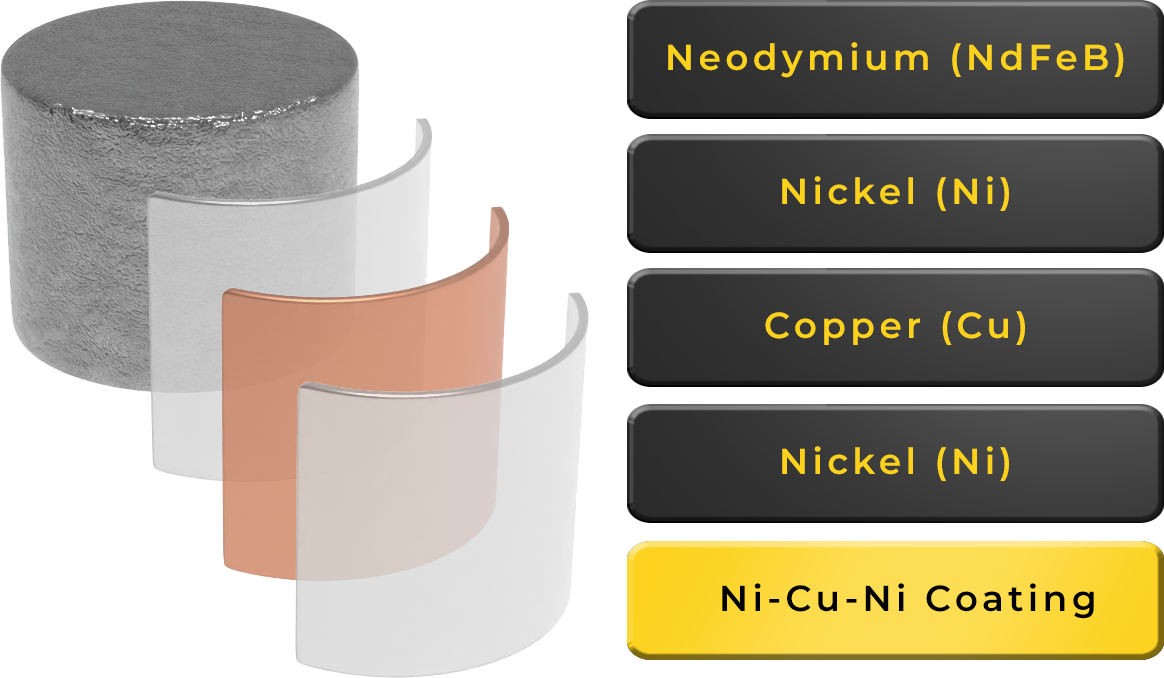

Surface coating is the most basic and common surface treatment method.

Types of Coating

The coating can be divided into electroplating, barrel electroplating, rack plating, electroless plating, and physical vapor deposition.

- Electroplating (EP) refers to the deposition of a metal or alloy layer with good adhesion on the substrate by electrolysis in order to obtain properties or dimensions that the substrate does not have;

- Barrel plating refers to the electroplating process of electrodepositing bulk workpieces in rotating, oscillating, or other moving containers;

- Rack plating is electroplating in which the parts to be plated are independently connected to the rack;

- Electroless Plating/Actocalytic Plating (AP) is the deposition of a metal coating by chemical rather than electrolytic methods;

- Physical vapor deposition (PVD) forms a covering layer on the surface of the substrate by evaporating and recondensing elements or compounds, usually under high vacuum conditions.

Another point we often mention is the adhesion of the coating, which is the force required to separate the different layers of the covering layer, or the force required to separate the covering layer from a certain area of the corresponding surface and the substrate.

Requirements for the substrate

Requirements for the substrate and precautions before electroplating (the substrate means the workpiece that needs to be treated on the surface):

- The structure of the matrix should be fine, uniform, dense, and have a certain stability, and there should be no cracks and pinholes visible to the naked eye on the surface. Its density should conform to the typical value in GB/T 13560. If the density does not meet this requirement, it should be confirmed through negotiation between the supplier and the purchaser.

- Surface-treated workpieces can be in various shapes, and their dimensional tolerances, shape deviations, surface conditions, etc. should be accepted for acceptance; for workpieces with special shapes and large dimensional differences in different directions, the acceptance requirements should be negotiated by the supplier, and the buyer.

- The magnitude of the residual magnetism of the workpiece will affect the quality of the coating, and the supplier and the buyer should agree in advance before the coating process.

- In order to prevent defects due to parts rolling and colliding with each other, chamfering can be performed before plating. The radius of curvature after chamfering can be in the range of 0.1mm~0.8mm. Excessive chipping, scoring, and abrasion should not occur after chamfering.

- The workpiece should be degreased and cleaned as required before plating.