Rare earth permanent magnet materials are new functional materials developed since the 1960s. They have been widely used in microwave communication technology, audio-visual technology, electrical engineering, instrumentation technology, computer technology, automation technology, automobile industry, petroleum industry, magnetic separation technology, bioengineering, magnetic therapy and fitness equipment, etc. Rare earth permanent magnet materials have become an important material basis for contemporary new technologies.

Application in microwave communication technology

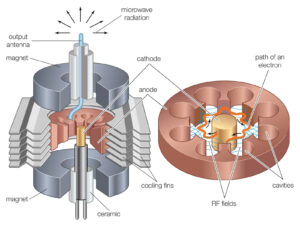

In radar technology, satellite communication, remote control and telemetry technology, electronic tracking, and electronic countermeasure technology, magnetrons, magnetron traveling wave tubes, cathode ray tubes, microwave ferrite isolators, circulators, etc. are required. All these devices use permanent magnets to generate a constant magnetic field to control the movement of electron beams, so as to achieve high-frequency or ultra-high-frequency oscillation, microwave signal (current, voltage or power) amplification, reception and display functions.

Application in electrical engineering

About 1/3 of the output of rare earth permanent magnet materials is used to manufacture various permanent magnet motors. There are many types, uses and varieties of permanent magnet motors. The capacity of the motors ranges from a few deciwatts to hundreds of kilovolt-amperes. They are widely used in modern science and technology and various sectors of the national economy. The advantages of permanent magnet motors are that they do not require excitation windings or exciters, save copper and electricity, are light in weight, small in size and have high specific power. The emergence of high-performance rare earth permanent magnet materials, especially Nd-Fe-B permanent magnet materials, has promoted the development of permanent magnet motors.

Application in instruments and timing devices

According to statistics, 10-15% of permanent magnet materials are used to manufacture various magnetoelectric instruments and timing devices. The stepper motor core of electronic watches is generally made of bonded permanent magnets.

Application in electroacoustic devices

About 15% of rare earth permanent magnet materials are used to manufacture electroacoustic devices. Electroacoustic devices are a general term for speakers (horns), microphones, pickups, hearing aids, stereo headphones, telephone receivers and electroacoustic sensors. The principles of electroacoustic devices are basically the same. When current passes through the voice coil in the air gap, it will vibrate under the action of the air gap magnetic field, causing the paper plate to vibrate and make a sound.

Application in magnetic machinery

Magnetic machinery is a new application field that has gradually developed after the emergence of rare earth permanent magnets. Magnetic machinery includes magnetic transmission or magnetic “gear”, magnetic brake, magnetic clamp, magnetic salvage, magnetic bearing, magnetic pump, magnetic valve, magnetic sealing door and magnetic lock, etc. There are many types of magnetic machinery, but their principles are the same, that is, using the repulsive force of the same polarity or the attractive force of opposite polarity of the magnet. For example, the magnetic transmission uses the principle of mutual attraction between opposite magnetic poles to form a non-contact transmission inside and outside the sealed or vacuum container. Its characteristics are that there is no contact and friction between the magnetic poles, and it can be used in vacuum systems or chemical industries; for example, magnetic bearings use the principle of mutual repulsion between the same polarity, and put two magnets with the same polarity opposite to each other to form a magnetic repulsive field and work in the field. There are two types of magnetic bearings: horizontal and vertical. They are mainly used in satellites, spacecraft, gyroscopes of high-speed aircraft, ultra-high-speed centrifuges, turbines of textile machines, electricity meters, special-purpose motors, precision instruments and electric meters. Satellites or spacecraft generally work under vacuum conditions. In a vacuum, mechanical bearings face serious lubrication and wear problems, which determine the life of satellites and high-speed aircraft. Magnetic bearings have no friction and do not require lubrication, so they can be used for a long time.

Application in transportation engineering

Trains made using the principle of mutual repulsion of the same magnetic poles are called maglev trains. The wheels of this train are not in contact with the track, and it relies on magnetic repulsion to suspend the body. This train is fast during operation, with a speed of up to 500km/h, while the speed of ordinary trains is less than 300km/h. In addition, there is no friction and noise, which is an ideal means of transportation in the future.

Application in magnetic separation technology

The technology of using magnetic method to separate ferromagnetic materials from non-ferromagnetic materials or magnetic atoms (ions) or magnetic molecules from non-magnetic atoms (ions) or non-magnetic molecules is called magnetic separation technology. Magnetic separation technology has been applied in mineral processing, raw material processing, water treatment, garbage treatment, chemical industry, food industry, and its application scope will be expanded day by day.