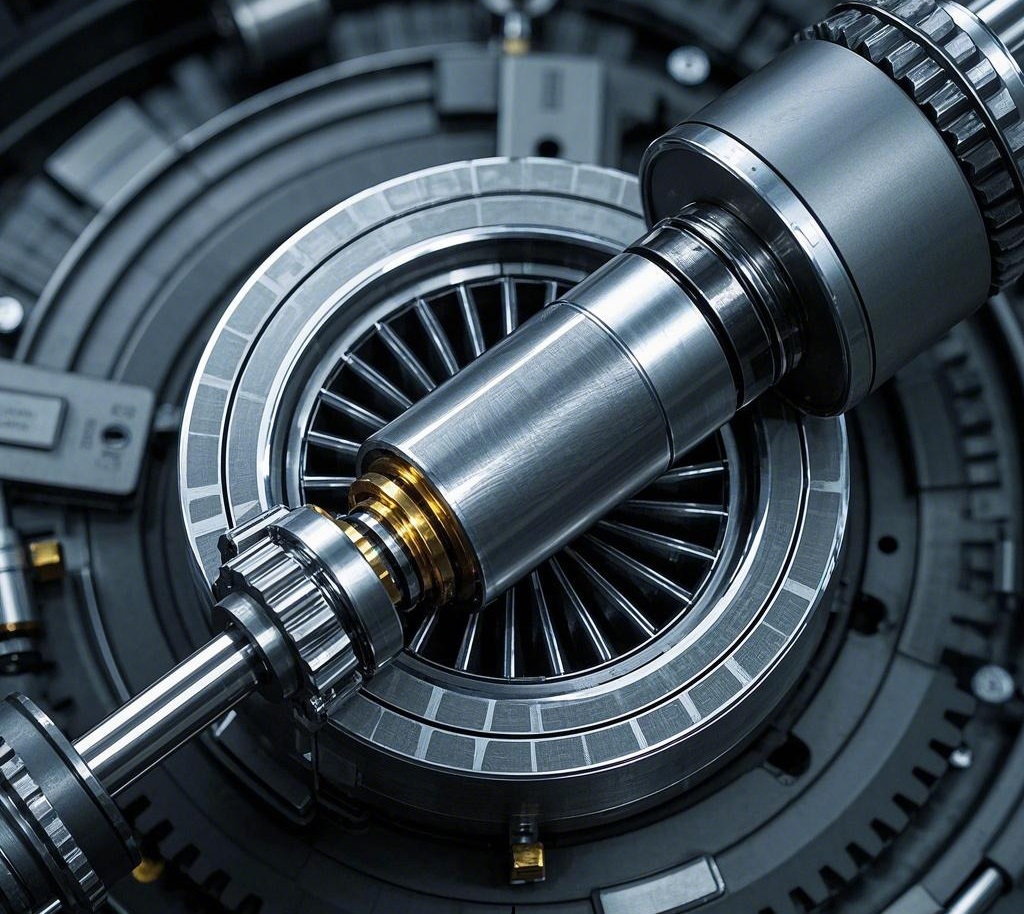

HS Magnet manufactures high-performance magnets, magnetic assemblies, precision thin metals, and high-speed magnetic rotor assemblies for highly efficient electric machines. Our engineers work with motor designers every day to optimize their permanent magnet rotor assembly designs.

The following magnets are usually used in high-speed magnetic rotor assemblies:

NdFeB magnets (Nd-Fe-B)

- Features:

NdFeB is the strongest permanent magnet material currently available. It has the characteristics of high remanence, high coercivity and high magnetic energy product. Its maximum magnetic energy product can reach more than 50MGOe (mega-Oersted), which enables it to generate a strong magnetic field in a small volume. The Curie temperature of this magnet is generally between 310-400 degrees Celsius. It can maintain good magnetic properties within a reasonable operating temperature range, which is important for high-speed magnetic rotor assemblies, because during high-speed operation, the rotor assembly may generate a certain amount of heat. - Application scenarios:

It is widely used in magnetic rotor assemblies of high-performance motors. For example, in the drive motor of an electric vehicle, due to the need for high torque density and high power density, NdFeB magnets can meet its requirements for magnetic field strength, thereby improving the efficiency and power output of the motor. At the same time, in some high-speed industrial motors, such as spindle motors for CNC machine tools, robot joint motors, etc., NdFeB magnets also play a key role, which helps to achieve the miniaturization and high-speed operation of motors.

Samarium cobalt magnets (Sm-Co)

- Features:

Samarium cobalt magnets have high magnetic properties, and their magnetic energy product can generally reach about 20-30MGOe. Its outstanding advantage is that the Curie temperature is high, which can reach about 700-800 degrees Celsius, which means that in high-temperature environments, samarium cobalt magnets can still maintain good magnetic properties. Moreover, samarium cobalt magnets have good chemical stability and strong corrosion resistance. - Application scenarios:

Suitable for some high-speed magnetic rotor components in harsh working environments, especially high-temperature environments. For example, in some motors in the aerospace field, the motors near the engine may be affected by the high-temperature environment. Samarium cobalt magnets can ensure that the magnetic rotor of the motor works normally at high temperatures and maintain the performance of the motor. In downhole motor equipment in industrial fields such as oil extraction, due to the high downhole ambient temperature, samarium cobalt magnets also have good application prospects.

Ferrite magnets (Ferrites)

- Features:

Ferrite magnets are a composite oxide sintered body, the main component of which is Fe₂O₃ (iron oxide). It is relatively cheap and has good chemical stability and corrosion resistance. Its magnetic energy product is generally around 3-5MGOe. Although its magnetic properties are not as good as those of NdFeB and SmCo magnets, it has a higher resistivity, which effectively reduces eddy current losses when working at high frequencies. - Application scenarios:

It is often used in some high-speed magnetic rotor components that do not require particularly high magnetic field strength but are more sensitive to cost. For example, it is widely used in some small household motors, such as fan motors, washing machine motors and other magnetic rotor components. In these application scenarios, the motor speed is high, but extremely high magnetic field strength is not required. Ferrite magnets can reduce production costs while meeting performance requirements.

High-performance electric machines are characterized by their rotational speed, system efficiency, power density, and ability to function in extreme conditions. Typically operating in excess of 50,000 revolutions per minute (RPM), these electrical machines run faster and hotter while achieving higher efficiency in a smaller package.

HS Magnet also manufactures Halbach arrays for high power density and high efficiency.

Turn to us for your next high-performance electric motor design challenge. Welcome to contact us to discuss your requirements.