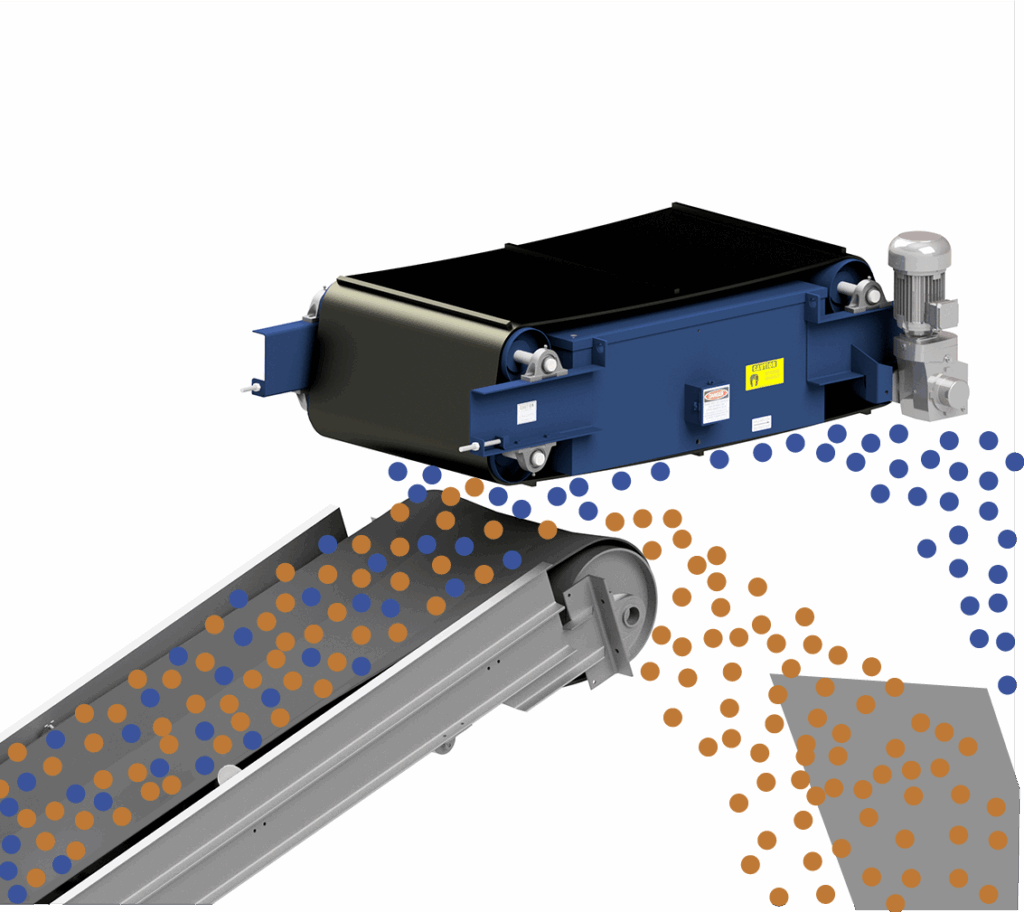

Magnetic separator is a device that utilizes the magnetic differences of various minerals to achieve mineral separation in an uneven magnetic field. Its principle mainly involves the following aspects: The magnetic differences of minerals Minerals in nature can be divided into strong magnetic minerals, weak magnetic minerals, and non-magnetic minerals according to their magnetic strength. […]

Author Archives: Tina Gao

One of the important raw materials of Ferrite magnet is Strontium Carbonate On March 6, 2025, a serious fire broke out at the Kandelium plant in Mexico. Kandelium is the largest overseas supplier of Strontium Carbonate, with an annual production capacity of 40,000 tons, accounting for 11% of global production. Most of its production capacity […]

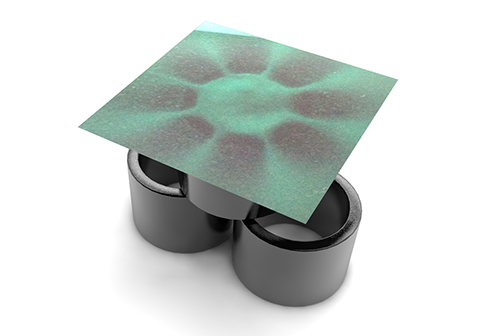

Magnets are mainly used in the nail industry to create cat-eye effects, make special patterns, and absorb nail tools. The following is a detailed introduction: Creating cat-eye effects Principle: Cat-eye nail polish contains magnetic particles. When the magnet is close to the uncured cat-eye glue, the magnetic field will align the magnetic particles in the […]

SmFeN magnet can replace NdFeB magnet in some processes. Advantages of SmFeN magnet Price advantage: The raw material cost of SmFeN permanent magnets is significantly lower than that of NdFeB permanent magnets, because the price of rare earth raw material samarium oxide is much lower than that of neodymium oxide. Performance advantage: SmFeN permanent magnet […]

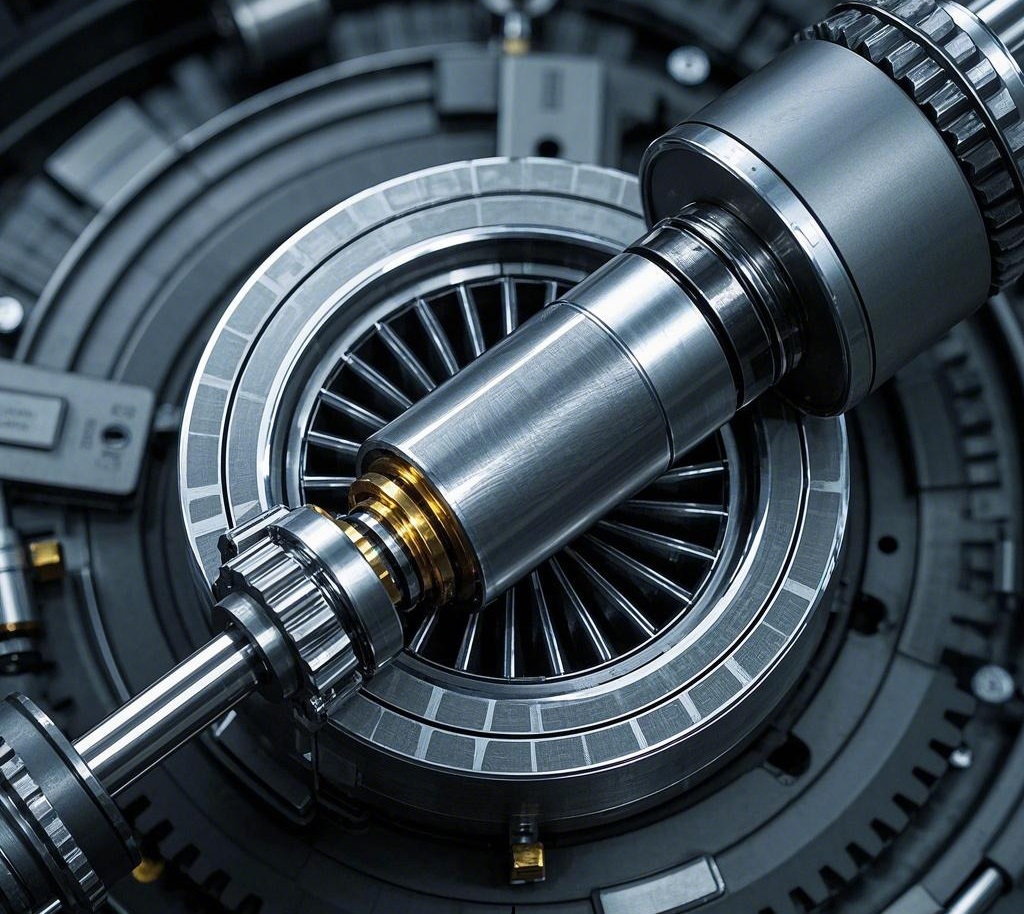

HS Magnet manufactures high-performance magnets, magnetic assemblies, precision thin metals, and high-speed magnetic rotor assemblies for highly efficient electric machines. Our engineers work with motor designers every day to optimize their permanent magnet rotor assembly designs. The following magnets are usually used in high-speed magnetic rotor assemblies: NdFeB magnets (Nd-Fe-B) Features: NdFeB is the strongest […]

Magnet has extensive and important applications in the field of new energy, and its application potential is huge. The following are some specific aspects: Magnet in New energy vehicle field Drive motor: Permanent magnet synchronous motor is the mainstream type of drive motor for new energy vehicles, and magnet is the key material of permanent […]

The air gap affects magnet selection, the air gap refers to the air separation between two magnetic components in a magnetic circuit, but is not limited to empty space; it may be composed of various non-magnetic materials, such as wood, plastic, or even coatings such as rubber or nickel. The presence of an air gap […]

Multipole magnets have extensive and important applications in many fields: Industrial field Motor manufacturing Multipole magnets are widely used in the drive motors of modern electric vehicles. For example, Tesla’s high-performance motors use multipole permanent magnets. By precisely controlling the distribution and changes of the multipole magnetic field, efficient conversion of electrical energy and mechanical […]

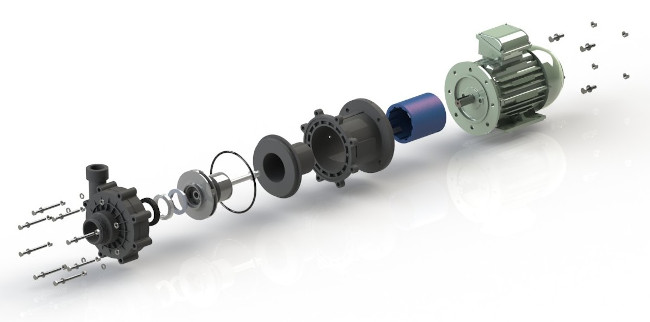

Samarium cobalt magnets are needed in magnetic pumps, mainly because they have many characteristics suitable for the working environment and performance requirements of magnetic pumps: High magnetism Samarium cobalt magnets have extremely high magnetic energy product and can generate a strong magnetic field. This feature allows sufficient attraction between the driving magnet and the driven […]

The advantages of AlNiCo cow magnet over other types of cow magnets are mainly reflected in the following aspects: Good temperature stability Wide range of application: AlNiCo magnets can work normally at high temperatures above 500℃, its Curie temperature can reach 860℃, and the maximum working temperature is about 550℃, while the upper limit of the […]