When you are trying to figure out which neodymium magnets to select for your design needs, you would always see the term “grade” or “N rating” from any supplier or manufacturer. Besides a few other criteria like coating, tolerance, and desired material grade must be defined for a neodymium magnet.

The material grade is the Maximum Energy Product, (BH)max, or the maximum strength that such magnet material can be magnetized to. In other words, it correlates to the magnetic flux output per unit volume. It is measured in units of million Gauss Oersted (MGOe), which is the product of attractive force (Gauss) and permanence of the force (Oersted) and is also equivalent to 7,958 kJ/m3. Generally bigger value indicates a more powerful magnet. The grade is determined during the initial steps of neodymium magnet manufacturing. Based on the exact recipes of the composition of the rare-earth ingredients for each corresponding material grade, our factory precisely weighs, melt, crush, mill and thoroughly mix them.

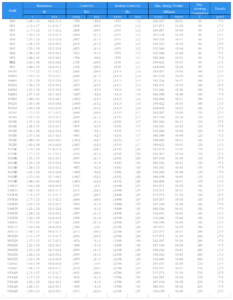

The material grades begin with the nomenclature “N” standing for neodymium magnets and followed by a 2-digit value ranging between 25 and 52 with 52 being the most powerful magnetic strength option. (However, theoretically, the highest grade can go all the way to N64, but it is not yet achieved in production.) Sometimes it ends with a letter(s) representing the Intrinsic Coercivity (Hci) of the material which directly relates to its maximum working temperature. Available grades are grouped as N35-N52 with no ending letter (80℃), N33M-N50M (100 ℃), N35H-N48H (120℃), N30SH-N45SH (150℃), N30UH-N40SH (180℃), N28EH-N38EH (200℃) and N30AH-N33AH (220℃). Degree Celsius is the corresponding maximum working temperature each grade can withstand before the magnet irreversibly lose a fraction of its magnetic strength.

A magnet grade is a good measure of the strength of a magnet. In general, higher numbers indicate a stronger magnet. The pull force from a magnet varies with the grade or N number. Double the N number and you’ll find roughly double the pull force.

What grade should you choose?

It depends on the application. If you need the highest strength in the smallest possible package at room temperature, grade N52 is the strongest available.

Many of our magnets are offered in grade N42, which is a great balance between cost, strength and performance at higher operating temperatures. You can get the same strength as an N52 magnet by using a slightly larger N42 magnet.

If you have slightly elevated temperatures, in the 140°F to 176°F range (60°C -80°C), N42 magnets might actually be stronger than N52. This is especially true if your magnet shape is very thin.

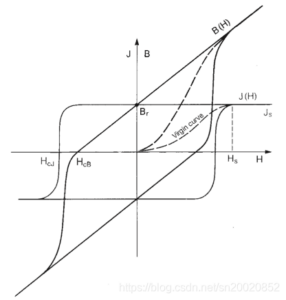

The performance of a magnetic material is defined by that material’s hysteresis curve, also known as a Demagnetization Curve or BH Curve. The Maximum Energy Product is the point on this curve where the B value multiplied by the H value is at its maximum.

At a point on the curve, multiply the “B” value (in kilo Gauss) by the “H” value (in kilo Oersted) to get the Maximum Energy Product (in Mega Gauss Oersted, or MGOe). For example, grade N42 has a Max Energy Product of 42 MGOe.

Magnets with a bigger Maximum Energy Product will have greater strength. Specifically, the shape of the BH Curve indicates both how strong a magnet is and how strong of a magnetic field you would need to demagnetize the magnet.

If you want to know more details of neodymium magnets, please feel free to contact sales06@hsmagnet.com, we can customize any size and grade for you according to your requirements.